The Indian manufacturing sector is in the midst of a profound transformation, rapidly moving from traditional production lines to intelligent, automated factory floors. At the heart of this evolution are the pioneering Ai manufacturing automation companies in India, which provide the critical technologies enabling this change. According to a NASSCOM report, this seismic shift is quantified by a staggering projection: digital technologies are expected to command 40% of the total manufacturing expenditure by 2025, a twofold increase from just 20% in 2021. This surge in investment is not merely a trend; it is a strategic pivot towards Industry 4.0, driven by the urgent need for greater efficiency, precision, and global competitiveness. These firms are instrumental in addressing core industrial challenges—from reducing operational costs and enhancing quality control to solving labor shortages. The national importance of this technological leap is underscored by collaborative initiatives like the ‘AI for India’ summit, which brings together industry, academia, and government to accelerate innovation. Many businesses are now looking for the best Ai manufacturing automation companies in India to guide their transition.

For business leaders and technical decision-makers, navigating this dynamic landscape to find the right technology partner is a mission-critical task. This article serves as a strategic guide, not just a directory. It presents a meticulously researched list of the Top Ai manufacturing automation companies in India, designed to help you identify and evaluate the ideal partner to drive your company’s next phase of growth. This List of Ai manufacturing automation companies in India is your first step toward building a more intelligent, resilient, and productive manufacturing future. The landscape of Ai manufacturing automation companies in India is vibrant and filled with specialists ready to tackle your unique challenges.

The Expanding Capabilities of AI in Manufacturing Automation

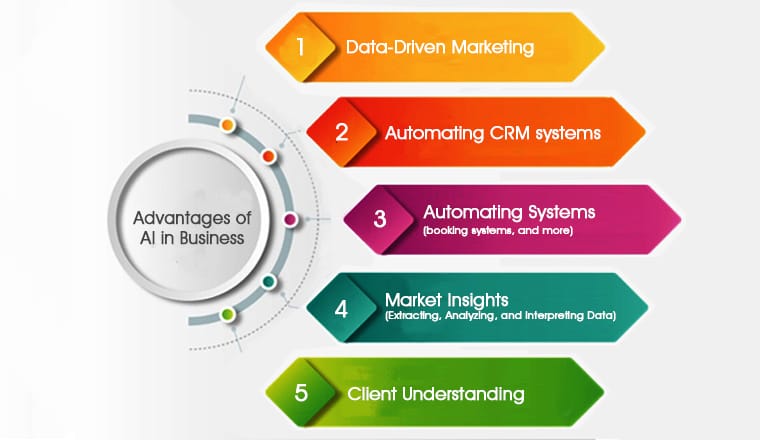

Before diving into the list of top providers, it is crucial to understand the specific capabilities that define the modern AI-driven manufacturing landscape. The market for Ai manufacturing automation companies in India is maturing, leading to the emergence of specialized verticals rather than generic, one-size-fits-all solutions. This segmentation means that a business leader’s first step is to identify their most pressing challenge—be it quality control, logistics, or operational analytics—and then seek a specialist. This understanding provides a clear framework for evaluating the Ai manufacturing automation companies in India on this list.

Trend 1: AI-Powered Visual Inspection

The era of manual or simple rule-based quality control is fading. AI-powered visual inspection has emerged as a transformative force, leveraging advanced computer vision to achieve near-perfect accuracy. These systems can identify microscopic defects, verify the correct assembly of complex components, and drastically reduce the rate of false positives that plague traditional methods. This technology is particularly impactful in high-stakes sectors like automotive, electronics, and pharmaceuticals, where precision is non-negotiable. Companies specializing in this area offer solutions that can be trained on a handful of images, making deployment faster and more accessible for factory workers without requiring them to be AI experts. Many leading Ai manufacturing automation companies in India specialize in this area.

Trend 2: The Rise of Autonomous Mobile Robots (AMRs)

Intralogistics—the movement of materials within a factory or warehouse—is being revolutionized by Autonomous Mobile Robots (AMRs). Unlike their predecessors, Automated Guided Vehicles (AGVs), which follow fixed paths, AMRs navigate dynamically using sensors and AI to map their environment and avoid obstacles in real-time. This adaptability makes them perfect for “brownfield” facilities, as they can be deployed with zero changes to existing infrastructure. They work collaboratively and safely alongside human employees, taking over repetitive and physically demanding transport tasks, thereby freeing up the human workforce for higher-value activities. This is a key service offered by many Ai manufacturing automation companies in India.

Trend 3: Predictive Maintenance and the Industrial IoT (IIoT)

The convergence of the Industrial Internet of Things (IIoT) and AI is giving rise to one of the most cost-effective applications in manufacturing: predictive maintenance. By analyzing data streams from IIoT sensors on machinery, AI algorithms can detect subtle anomalies and predict equipment failures before they occur. This capability allows manufacturers to shift from a reactive or scheduled maintenance model to a proactive, predictive one. The result is a dramatic reduction in unplanned downtime, optimized maintenance schedules, and extended machinery lifespan. Understanding these systems is key, as is knowing what are AI agents and how they can be deployed by Ai manufacturing automation companies in India to manage these complex, data-rich environments.

Ready to explore AI solutions?

Discover Our AI ServicesWhy Trust Our Insights?

This report is built on a foundation of deep industry experience and a commitment to rigorous, unbiased analysis, especially when evaluating Ai manufacturing automation companies in India. The selection process is guided by several core principles that ensure the information you receive is credible, relevant, and authoritative.

- 20+ Years of IT Domain Expertise: Founded in 2003, this analysis is backed by over two decades of hands-on experience in the global technology landscape, navigating multiple waves of technological disruption and innovation.

- ISO Certified & Audited: The methodologies adhere to rigorous international standards for quality management (ISO 9001-2015) and information security (ISO 27001), ensuring a disciplined and reliable process.

- Early Adopters of Emerging Tech: A proactive approach to research and development ensures a perspective that is always at the forefront of innovation, from the early days of enterprise software to the current frontiers of AI and Blockchain.

- Research-Backed Solutions: Every solution and recommendation is grounded in deep research and an end-to-end understanding of the complexities of custom software development and technology integration.

- Dedicated Development Teams: With extensive experience in building and deploying enterprise-grade solutions, there is a profound understanding of what it takes to succeed, including expertise in how to build and manage a dedicated development team.

Our Selection Criteria: How We Identified India’s Top AI Automation Partners

Identifying the genuine leaders among the many Ai manufacturing automation companies in India requires a stringent and multi-faceted evaluation process. This list is the result of a comprehensive methodology that combines quantitative market analysis with qualitative assessments of technological prowess and customer impact. The process began by reviewing public data from industry aggregators like Clutch and other specialized reports to identify companies that are consistently recognized as leaders in the automation space. This initial pool was then filtered through a rigorous set of criteria to ensure every company listed is not only an innovator but also a viable and strategic partner for manufacturing enterprises. This is how we selected the best Ai manufacturing automation companies in India.

The final selection was based on the following key factors:

- Laser-Focus on Manufacturing: Prioritizing companies whose core offerings are AI-driven solutions specifically designed for and deployed within the manufacturing sector.

- Proven Market Impact: Assessing client portfolios, public case studies, and credible testimonials for concrete evidence of successful, real-world deployments and measurable ROI.

- Technological Innovation: Evaluating the sophistication of their proprietary technology, whether it involves advanced robotics, no-code computer vision platforms, or scalable IIoT analytics engines.

- Appropriate Company Size: Selecting firms that are agile, specialized, and focused, deliberately avoiding mega-corporations to ensure a list of comparable partners who are leaders in this specific niche.

- Strong India Presence: Ensuring that each company has a significant operational, R&D, and support footprint in India, demonstrating a deep commitment to and understanding of the local market dynamics. Many Ai manufacturing automation companies in India fit this profile.

The List of Top 10 Ai manufacturing automation companies in India

The following companies represent the forefront of AI-driven innovation in India’s manufacturing sector. Each profile provides the essential data points needed to begin your evaluation process. The landscape of Ai manufacturing automation companies in India is diverse, offering both specialized products and custom development services. This distinction is critical; some challenges are best met with an off-the-shelf product, while others require a bespoke solution built from the ground up. This list empowers you to make that strategic choice among the available Ai manufacturing automation companies in India.

1. Softlabs Group ⭐ Top Pick

Pioneering custom AI solutions, 20+ years of enterprise software expertise, end-to-end development partner, driving digital transformation, from concept to deployment. Softlabs Group is a premier choice among Ai manufacturing automation companies in India, capable of building bespoke systems that solve unique challenges where off-the-shelf products fall short. They offer more than just automation; they deliver a competitive edge through tailored technology.

- Company Name: Softlabs Group

- Company Size: 51-200 employees

- Hourly Rate: $8-$45

- Website: https://www.softlabsgroup.com/

- Location: Mumbai, Maharashtra

- Contact: +91 7021649439

- Email: business@softlabsgroup.com

- Industries Catered: Manufacturing, Logistics, Healthcare, Fintech, Government, E-commerce, Real Estate, Insurance, Energy, Education

- Awards and Accreditations: ISO 9001-2015, ISO 27001, GovTech Award at Graham Bell Awards 2025

- Products and Services: Custom AI/ML Development, Industrial IoT (IIoT) Solutions, Software Product Development, Software Development Outsourcing, Mobile App Development, Blockchain Development, Big Data Solutions, IT Consulting

- Tech Stack Used: Python (TensorFlow, PyTorch), Computer Vision (OpenCV), IIoT Platforms, Edge Computing (Nvidia Jetson), .NET, Java, Cloud (AWS, Azure)

- Manufacturing Integration: Expertise in creating custom APIs for seamless integration with existing MES and ERP systems. Proficient in connecting with industrial hardware via PLC communication protocols (e.g., Modbus, OPC-UA) to bridge the gap between legacy machinery and modern AI analytics.

- Notable Case Studies:

- AI-Based Fleet & Compliance Management: For a UK-based client in the construction industry, Softlabs developed a comprehensive AI-driven platform to manage fleet logistics, monitor worker safety through PPE detection, and ensure regulatory compliance. The solution optimized material transport and enhanced operational safety.

- AI-Powered Inventory Tracker: Developed an AI solution to automate inventory tracking in a warehouse setting. The system uses computer vision to monitor stock levels, reducing manual errors and providing real-time data for better supply chain management, showcasing expertise in AI/ML development.

2. Addverb Technologies

Global robotics and warehouse automation leader, end-to-end intralogistics solutions, extensive hardware and software portfolio, enabling future-ready supply chains, backed by major industry investment. A significant player in the field of Ai manufacturing automation companies in India.

- Company Name: Addverb Technologies Private Limited

- Company Size: 1000-2000 employees

- Hourly Rate: Proprietary Information

- Website: https://addverb.com/

- Location: Noida, Uttar Pradesh

- Contact: automate@addverb.com (Email contact preferred)

- Email: automate@addverb.com

- Industries Catered: E-commerce, Retail, FMCG, Pharmaceuticals, 3PL, Automotive, Manufacturing

- Awards and Accreditations: Multiple industry awards for robotics and automation solutions.

- Products and Services: Autonomous Mobile Robots (AMRs), Sorting Robots (Zippy), ASRS Systems (Multi-Pro), Carton Shuttles (Quadron), Picking Technologies (Pick-To-Light, Voice Picking), Warehouse Management Software (Optimus WMS), Fleet Management System (Movect)

- Tech Stack Used: Robotics Operating System (ROS), Python, C++, AI/ML for navigation, GCP, Docker, Kubernetes

- Manufacturing Integration: Integrates with standard WMS and ERP systems. Robots can communicate with other factory hardware like conveyors.

- Notable Case Studies:

- Coca-Cola Warehouse Automation: Implemented a pallet shuttle ASRS system for Coca-Cola, significantly increasing storage density and throughput in their warehouse, enabling faster and more efficient distribution of products.

- Unilever India Automation: Deployed a comprehensive automation solution for Unilever’s warehouse, including carton shuttles and sorting robots, to streamline their order fulfillment process for a wide range of consumer goods, improving accuracy and speed.

3. Lincode Labs

AI-powered visual inspection specialist, no-code platform for factory workers, supercharging legacy machine vision systems, enabling real-time quality control, delivering rapid ROI for manufacturers. A niche leader within the Ai manufacturing automation companies in India.

- Company Name: Lincode Labs Inc.

- Company Size: 11-50 employees

- Hourly Rate: Proprietary Information

- Website: https://lincode.ai/

- Location: Bengaluru, Karnataka

- Contact: (947) 376-0618 (US Number)

- Email: info@lincode.ai

- Industries Catered: Automotive, Semiconductor, Electronics, Aerospace & Defense, Food & Beverage, Printing & Packaging

- Awards and Accreditations: Best Small Business Award 2024 (Michigan Celebrates Small Business), Best Manufacturing Technology 2024 (Centrepolis Accelerator)

- Products and Services: LIVIS (Lincode Intelligent Visual Inspection System), No-Code AI Platform, AI Models for Defect Detection, Assembly Verification, Label Inspection, Data Traceability, Analytics & Reporting

- Tech Stack Used: Deep Learning (CNNs), Computer Vision, Edge AI, Python, C++, Hardware Agnostic Platform

- Manufacturing Integration: Platform connects with most industrial cameras and PLCs to exchange signals on the production line.

- Notable Case Studies:

- Automotive Catalyst Manufacturer: Solved the complex problem of detecting plugged cells in catalysts, an issue other vendors could not address. The deployed LIVIS solution is running effectively and is being considered for global rollout.

- Robotics Integration Company: Partnered with an integrator to add advanced AI vision to robotic arms for inspection and pick-and-place applications, overcoming the limitations of conventional imaging processes for Body-in-White (BIW) automation lines.

See our solutions in action.

View Our Case Studies4. Ati Motors

Developer of autonomous mobile robots (AMRs), focused on material movement in factories and warehouses, enabling seamless integration with existing workflows, both indoors and outdoors. A key innovator among Ai manufacturing automation companies in India.

- Company Name: Ati Motors Inc.

- Company Size: 201-500 employees

- Hourly Rate: Proprietary Information

- Website: https://atimotors.com/

- Location: Bengaluru, Karnataka

- Contact: (248) 943-4526 (US Number)

- Email: info@atimotors.com

- Industries Catered: Automotive, Logistics, Warehousing, General Manufacturing, E-commerce

- Awards and Accreditations: ISO3691-4 Safety Certified AMRs

- Products and Services: Sherpa line of AMRs (Sherpa Tug, Sherpa Lite, Sherpa Pivot, Sherpa Lifter), Robots-as-a-Service (RaaS), AMR Fleet Planning & Simulation, Robo Operations Centre (ROC), 24/7 Support

- Tech Stack Used: AI, 3D LiDAR, VSLAM Navigation, Robotics Operating System (ROS), C++, Python

- Manufacturing Integration: Fleet management software can integrate with MES/WMS for task management. Designed for minimal infrastructure changes.

- Notable Case Studies:

- MNC Auto OEM: Deployed Sherpa Tug AMRs to automate the movement of components to the assembly line across three shifts. This freed up human workers for higher-value tasks, reduced variance in material delivery times, and significantly improved operational safety.

- Forvia & Hyundai Deployments: Deployed hundreds of Sherpa robots across multiple scaled sites in North America for leading manufacturers like Forvia and Hyundai, demonstrating the solution’s robustness and scalability in demanding automotive environments.

5. Peppermint Robotics

Specialist in autonomous cleaning and material handling robots, providing intelligent solutions for industrial and commercial environments, focused on efficiency, sustainability, and data-driven analytics.

- Company Name: Peppermint Robotics (Aubotz Labs Private Limited)

- Company Size: 51-100 employees

- Hourly Rate: Proprietary Information

- Website: https://www.peppermintrobotics.com/

- Location: Pune, Maharashtra

- Contact: +91 89567 10044

- Email: info@getpeppermint.co

- Industries Catered: Manufacturing, Pharmaceutical, Healthcare, Commercial Real Estate, Aviation, Retail

- Awards and Accreditations: Supported by SINE IIT-Bombay & Qualcomm

- Products and Services: Robotic Scrubber Dryers (SD20, SD45, SD100), Robotic Tug & Tow (TUG1000), Peppermint OS, Real-time Reporting Dashboard, Robots-as-a-Service (RaaS)

- Tech Stack Used: AI-based Navigation, LiDAR, 3D Depth Sensors, Cloud Analytics (AWS/Azure), Python

- Manufacturing Integration: Provides data output through cloud dashboards for operational analytics.

- Notable Case Studies:

- Bosch Manufacturing Plant (Bengaluru): Deployed two Peppermint robots for floor cleaning across two shifts. The solution resulted in a 50% reduction in manpower, a 33% reduction in cleaning machines, higher productivity, and up to 20% water savings, with automated night shift cleaning reports.

- Pharmaceutical Manufacturing: Utilized robotic floor cleaning to lower the risk of contamination in sterile environments. The autonomous robots ensure adherence to specific cleaning requirements, reduce human error, and help comply with stringent industry regulations.

6. SwitchOn

AI-powered quality inspection provider, focused on eliminating manufacturing defects with a computer vision platform, enabling high-speed inspection with high accuracy for zero-defect production lines.

- Company Name: SwitchOn Inc.

- Company Size: 25-50 employees

- Hourly Rate: Proprietary Information

- Website: https://switchon.io/

- Location: Bengaluru, Karnataka

- Contact: +91 9535288345

- Email: info@switchon.io

- Industries Catered: Automotive, Pharmaceutical, Consumer Goods, Electronics, Precision Manufacturing

- Awards and Accreditations: Backed by notable investors including Axilor Ventures, Pi Ventures, and Micelio.

- Products and Services: DeepInspect AI-powered Inspection System, Quality Inspection as a Service, Edge-based Inspection Software, Surface Defect Inspection, Process Gap Identification, Optical Character Recognition (OCR)

- Tech Stack Used: Edge AI (Nvidia/Intel), Deep Learning, Computer Vision, Python, C++, IIoT

- Manufacturing Integration: System can integrate with PLCs for pass/fail signals and send quality data to MES/SCADA systems.

- Notable Case Studies:

- Denso Corporation: Implemented the SwitchOn DeepInspect system to automate the inspection of starter switch caulking. The system successfully identified defects as small as 100-150 microns in under 11 seconds per part, improving quality and reducing labor costs.

- Large FMCG Company (India): Deployed DeepInspect for 100% AI-powered inspection on manufacturing lines, resulting in a 30x reduction in quality defects. The entire plant was brought online within a 4-week deployment cycle using simple hardware.

7. Unbox Robotics

Swarm intelligence robotics specialist, elevating fulfillment and distribution with vertical robotic sortation, enabling fast, scalable, and space-efficient parcel sorting for logistics and e-commerce.

- Company Name: Unbox Robotics

- Company Size: 51-200 employees

- Hourly Rate: Proprietary Information

- Website: https://unboxrobotics.com/

- Location: Pune, Maharashtra

- Contact: NA (Contact form on website)

- Email: NA (Contact form on website)

- Industries Catered: E-commerce, Retail, Logistics, 3PL, Postal & Parcel Services

- Awards and Accreditations: Backed by 3one4 Capital, Sixth Sense Ventures, and Entrepreneurs First.

- Products and Services: Vertical Robotic Parcel Sortation, Order Consolidation Solutions, Swarm Intelligence Platform, Plug-and-Play Configurable Robotics

- Tech Stack Used: AI-based Swarm Intelligence, Robotics Operating System (ROS), Python, Computer Vision

- Manufacturing Integration: System integrates with WMS and OMS to help automate sorting processes.

- Notable Case Studies:

- E-commerce Fulfillment: Deployed their robotic sorting system to help e-commerce players consolidate customer orders and sort parcels based on final delivery locations, reducing physical space requirements by 50-70% and achieving 99.9% sorting accuracy.

- Logistics Hubs: Implemented their solution in distribution centers to automate parcel sorting, increasing throughput and allowing logistics companies to scale operations dynamically without significant capital expenditure or long implementation times.

8. Peer Robotics

Collaborative mobile robotics company, building intelligent robots that learn directly from humans, focused on making automation simple and accessible for small and medium-scale manufacturers.

- Company Name: Peer Robotics

- Company Size: 11-50 employees

- Hourly Rate: Proprietary Information

- Website: https://www.peerrobotics.ai/

- Location: Gurugram, Haryana

- Contact: NA (Contact form on website)

- Email: NA (Contact form on website)

- Industries Catered: Manufacturing, Warehousing, Automotive, Logistics

- Awards and Accreditations: Partnered with Nvidia Inception Program and Intel Partner Alliance.

- Products and Services: Intelligent Material Movement Solutions (Pallet, Trolley, Bin), Collaborative Mobile Robot Platforms (Peer 3000, RM 500, RM 250), Peer Dashboard for fleet management, Human-feedback learning systems

- Tech Stack Used: Human-in-the-loop AI, Lidar/Camera Fusion, Edge Computing (Nvidia Jetson), ROS

- Manufacturing Integration: Designed for simple deployment. Fleet management system can connect with MES for assigning tasks.

- Notable Case Studies:

- SME Manufacturing Automation: Deployed AMRs in small and medium-sized manufacturing facilities to automate kit movement from storage to production lines. The robots learn paths from human operators, eliminating the need for complex programming and enabling rapid deployment in existing infrastructures.

- Assisted Kitting on Factory Floor: Implemented their kitting solution where robots assist workers in picking parts for assembly kits. The robot autonomously follows the worker and transports the completed kit, reducing manual effort and improving workflow efficiency.

9. DiFACTO Robotics and Automation

Leading Indian robotic automation solutions provider, extensive experience in automotive and general manufacturing, offering customized systems, standard products, and end-to-end automation services.

- Company Name: DiFACTO Robotics and Automation Pvt Ltd

- Company Size: 201-500 employees

- Hourly Rate: Proprietary Information

- Website: https://difacto.com/

- Location: Bengaluru, Karnataka

- Contact: +91 796 508 1522

- Email: ajay@difacto.com

- Industries Catered: Automotive, Automotive Suppliers, Aerospace, Construction Equipment, Electrical Machinery, Foundry, General Manufacturing

- Awards and Accreditations: Acquired RoboFinish IPR portfolio from Grind Master.

- Products and Services: Robotic Welding Systems, Robotic Assembly Solutions, Robotic Material Handling, Customized Automation Solutions, Standard Products (Gantries, Positioners), Automation Services, Dross Skimming Systems

- Tech Stack Used: Multi-brand Robot Programming (Fanuc, KUKA, ABB), PLC Programming (Siemens, Rockwell), Vision Systems (Cognex, Keyence), Offline Simulation (RoboDK)

- Manufacturing Integration: Experienced in integrating robotic systems with various PLC brands and factory machinery.

- Notable Case Studies:

- Pharmaceutical Leaflet Pasting: Developed a high-speed, flexible robotic application for pasting Patient Information Leaflets on medicine bottles for a leading pharmaceutical company. The system handles 90 PILs per minute and over 40 different sizes, fully compliant with pharma industry standards.

- Automotive Component Assembly: Provided robotic assembly solutions for manufacturing automotive components like pumps, motors, and gearboxes. The systems use vision for part identification and are configured with single or multiple robots to meet manufacturing and quality demands.

10. Unseen Era

Industrial automation engineering services and solutions provider, focused on vision systems, IIoT, and sensing solutions for a wide range of manufacturing verticals since 2010.

- Company Name: Unseen Era Technologies Private Limited

- Company Size: 11-25 employees

- Hourly Rate: Proprietary Information

- Website: https://www.unseenera.com/

- Location: Pinjore, Haryana

- Contact: +91-7206-86-5596

- Email: info@unseenera.com

- Industries Catered: Pharmaceuticals, Food & Beverage, Automotive, Chemical, FMCG, Cosmetics

- Awards and Accreditations: ISO 9001:2015, ISO 14001:2015

- Products and Services: Vision Systems (OCR/OCV, Smart Cameras), IIoT Solutions (Energy & Production Management, Predictive Maintenance), Industrial Sensors, Safety Products, Custom Automation Projects, Flow Wrap Packaging Machines

- Tech Stack Used: Vision Systems (HikRobot, FLIR), Industrial Sensors (Banner), PLC Programming, SCADA/HMI Development

- Manufacturing Integration: Integrates vision systems and sensors with PLCs and SCADA systems for data and control.

- Notable Case Studies:

- FMCG Packaging Inspection: Deployed vision systems for a client like Reckitt Benckiser to perform high-speed inspection of packaging, verifying labels, checking seal integrity, and ensuring product quality before shipping.

- Automotive Part Sensing: Integrated advanced Banner sensors for an automotive client like Asian Paints (supplies coatings) to ensure precise detection and positioning of components during automated assembly processes, improving quality and reducing errors.

A Strategic Guide to Partnering with These AI Companies

Engaging with any of the Best Ai manufacturing automation companies in India requires a strategic approach. To ensure a successful partnership and maximize your return on investment, it is vital to move beyond a simple vendor transaction and build a collaborative relationship. This is crucial when working with top-tier Ai manufacturing automation companies in India. This section provides actionable tips for business leaders looking to initiate projects and build lasting partnerships with the firms on this list.

-

Define Your Problem, Not the Solution

Before you approach any vendor, clearly document the business problem you are trying to solve. Are you aiming to reduce inspection errors by 30%? Increase material throughput by 25%? Or cut unplanned downtime by half? A well-defined problem statement allows potential partners to propose the most effective solution, whether it’s an off-the-shelf product from a company like SwitchOn or a fully custom-built system from a development partner. This clarity is essential for all Ai manufacturing automation companies in India.

-

Start with a Proof-of-Concept (PoC) or Pilot Project

Instead of committing to a large-scale, factory-wide deployment from the outset, propose a smaller, well-defined pilot project. A successful pilot de-risks the financial investment, provides tangible data on the potential ROI, and serves as a real-world test of the partnership’s dynamics, communication, and support capabilities.

-

Prioritize Integration Capabilities

Your factory already has a technology ecosystem, including ERP (Enterprise Resource Planning), MES (Manufacturing Execution Systems), and various PLCs (Programmable Logic Controllers). A critical evaluation point is a potential partner’s ability to seamlessly integrate their solution into your existing infrastructure. This is where a custom software firm often excels, as they can build the necessary APIs and data pipelines for a truly connected system. The best Ai manufacturing automation companies in India will have strong integration experience.

-

Scrutinize the Data Strategy and Security

AI solutions are powered by data. You must have a clear understanding of your partner’s data strategy. Ask critical questions: Where will the data be stored (on-premise or cloud)? Who owns the data and the trained AI models? What security protocols are in place to protect your sensitive operational data? A transparent partner will have clear and robust answers to these questions.

-

Plan for Scalability from Day One

Think beyond the immediate problem. The ideal solution should be architected for growth. Discuss the scalability roadmap with potential partners. How will the solution be expanded to other production lines or deployed across multiple factory locations? A partner with strong architectural expertise will design a solution that grows with your business, not one that needs to be replaced in a few years. This foresight is a hallmark of leading Ai manufacturing automation companies in India.

-

Evaluate the Team and Post-Deployment Support

Technology is only half of the equation. The expertise, cultural fit, and responsiveness of the team you will be working with are equally important. Evaluate their communication processes, project management methodologies, and, crucially, their post-deployment support structure. A strong partnership is built on trust and reliable support long after the initial go-live.

Conclusion: Automating Your Future in Manufacturing

India has cultivated a vibrant and highly specialized ecosystem of Ai manufacturing automation companies in India, each equipped to solve the most pressing challenges of modern industry. From AI-powered visual inspection that achieves unparalleled quality control to autonomous robots transforming factory logistics, the solutions are available and proven. This list demonstrates that the market offers a strategic choice: you can select highly refined, product-based solutions for specific tasks or engage a partner for end-to-end custom development to tackle unique and complex operational challenges. The journey with the Best Ai manufacturing automation companies in India is no longer a distant vision but an immediate strategic imperative.

The next frontier is already emerging. It is not just about automation but hyper-automation, where intelligent systems not only execute tasks but also learn, adapt, and self-optimize entire value chains in real-time. This future of a fully connected, predictive, and resilient manufacturing operation is within reach. The question for business leaders is no longer *if* they should invest in AI automation, but *how quickly* they can deploy it to build an enduring competitive advantage. The partners who can help you achieve this are on this list. Choosing the right partner from the many Ai manufacturing automation companies in India is your next step. It is time to build the future.

Have a project in mind?

Contact Us Today