What You’ll Discover Inside!

- Learn why the global market for AI in manufacturing is projected to surge from $7 billion to nearly $48 billion by 2030.

- Understand why your traditional Manufacturing Execution System may now be a strategic liability rather than an asset.

- See how leading companies are leveraging AI to slash unplanned machine downtime by as much as 50%.

- Discover how Generative AI allows your operators to ask simple questions and get instant, expert troubleshooting advice

- Find out why Gartner mandates that 75% of all MES systems will be cloud-deployed by 2030

- Uncover the specific AI use case that reduced the time to generate complex production schedules by 96% for a global manufacturer.

Manufacturing Execution System: From a System of Record to a System of Intelligence

The global manufacturing landscape is in the throes of a profound transformation. Faced with relentless pressure to enhance productivity, slash costs, and navigate increasingly volatile supply chains, the old paradigms of production management are no longer sufficient. In India, this global shift is amplified by the ambitious “Make in India” initiative, positioning industrial hubs like Mumbai at the epicentre of a new wave of technological adoption. At the heart of this evolution lies a critical operational tool: the Manufacturing Execution System (MES).

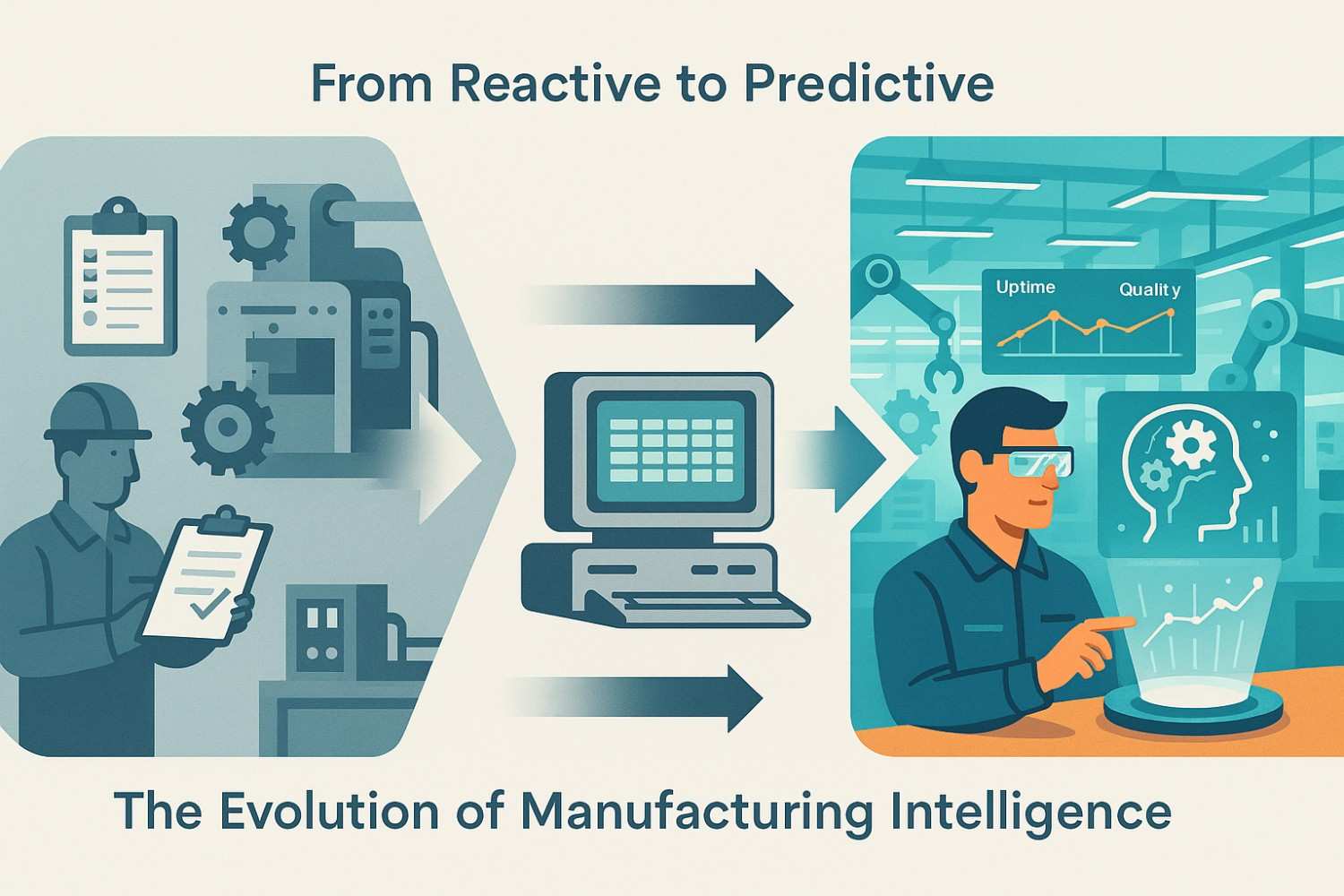

For decades, the traditional Manufacturing Execution System has served as the indispensable digital backbone of the factory floor. Its core function has been to monitor, track, document, and control the entire production lifecycle, bridging the gap between enterprise-level planning and shop-floor machinery. It has been the system of record, meticulously documenting what has already happened. However, in today’s hyper-competitive environment, being a reactive historian is a liability. The market now demands predictive foresight and prescriptive intelligence.

This article posits a clear thesis: the integration of Artificial Intelligence is not an incremental feature upgrade for the MES; it’s how you operationalize AI in Manufacturing. This evolution is transforming the Manufacturing Execution System from a passive data repository into a proactive, cognitive engine. It is becoming the central brain of the smart factory—a true AI Manufacturing Execution System capable of not just monitoring operations but predicting outcomes, prescribing actions, and, ultimately, driving the entire facility toward a state of autonomous self-optimization. For business and technology leaders, understanding this transformation is paramount to navigating the next frontier of industrial competition.

Section 1: Why AI is Now Essential for Your Manufacturing Execution System

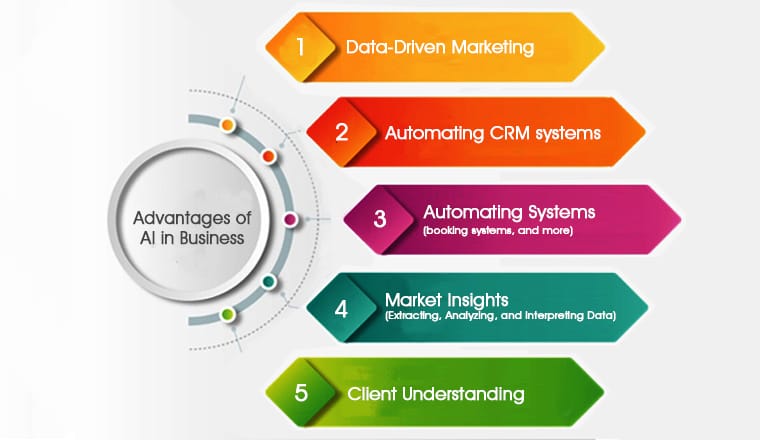

The integration of AI into manufacturing is not a futuristic concept; it is a present-day economic force that is reshaping the industry at an unprecedented speed. For manufacturing leaders, understanding the scale and velocity of this change is the first step toward strategic adaptation. The “wait and see” approach has expired; the era of the intelligent factory is here.

The Market Imperative

The financial momentum behind this shift is staggering. As per GrandViewResearch report, the global market for AI in manufacturing is projected to surge from USD 7.09 billion in 2025 to an astounding USD 47.88 billion by 2030, reflecting a compound annual growth rate (CAGR) of 46.5%. This exponential growth is not driven by hype, but by the tangible value AI delivers in efficiency, quality, and cost reduction. For Indian manufacturers aiming to compete on a global scale, ignoring this technological wave is a direct threat to long-term viability.

Business adoption rates confirm this urgency. In 2024, a report released by Stanford university, an estimated 78% of organizations reported using AI in at least one business function, a significant leap from 55% the previous year. Projections from Deloitte’s 2025 outlook further solidify this, identifying targeted AI investment as a primary driver of operational efficiency for the year ahead. This rapid, widespread adoption signals a clear market consensus: AI is no longer optional.

The Evolution of MES

A traditional Manufacturing Execution System, or MES, is fundamentally a software solution designed to manage and monitor work-in-process on the factory floor. Over time, the scope of MES has broadened, often being referred to as Manufacturing Operations Management (MOM) systems, which are now recognized as the central pillar of any digital transformation strategy in manufacturing. However, even these advanced systems are being redefined by the capabilities that AI unlocks.

Gartner’s 2025 Mandates for Modern MES

Leading industry analyst firm Gartner has tracked this evolution closely. Its 2025 Market Guide for MES highlights that the vendor landscape is rapidly adapting to keep pace with agile startups specializing in AI and the Industrial Internet of Things (IIoT). For manufacturing leaders evaluating their next steps, Gartner’s analysis points to several non-negotiable trends for any modern AI MES Software:

- Cloud-Native Architecture: The future of MES is in the cloud. Gartner predicts that 75% of MES systems will be cloud-deployed by 2030, a dramatic increase from 38% today. This shift is critical as it enables greater scalability, faster deployment times, and a transition from heavy capital expenditure (CapEx) to more flexible operating expense (OpEx) models, making advanced MES solutions accessible to a broader range of businesses.

- Composable & Interoperable Platforms: The era of rigid, monolithic systems is over. Businesses are now demanding composable platforms built on open standards and APIs (like REST, MQTT, and OPC UA). A modern MES must integrate seamlessly with the existing technology stack—including Enterprise Resource Planning (ERP), Product Lifecycle Management (PLM), and SCADA systems—to eliminate data silos and reduce long-term technical debt.

- Low-Code/No-Code Extensibility: The shortage of specialized AI and software development talent is one of the biggest barriers to adoption. Consequently, low-code/no-code capabilities have become a key differentiator for MES platforms. These tools empower a company’s own process engineers and operations staff—the people who understand the factory floor best—to configure and customize workflows, dashboards, and interfaces without writing extensive code, drastically accelerating deployment and adaptation.

- Industry-Specific Functionality: A generic, one-size-fits-all MES is no longer effective. In highly regulated or specialized sectors, industry-specific functionality is crucial. Gartner strongly recommends that potential users evaluate vendors based on their proven, vertical-specific solutions for industries such as semiconductor, medical devices, automotive, or aerospace and defense. This approach minimizes the need for costly and risky customization while ensuring compliance and addressing unique process requirements from day one.

These trends point toward a significant shift in how manufacturing intelligence is accessed and deployed. Historically, powerful MES solutions were the exclusive domain of large multinational corporations with the substantial capital and specialized IT teams required for implementation and maintenance, as noted in user reviews of complex systems like SAP’s. The move to cloud-based, subscription models lowers this financial barrier, converting a massive upfront investment into a manageable operational expense. However, cost is only one part of the equation. The persistent shortage of skilled AI and data science professionals remains a critical hurdle for many organizations.

This is where the rise of low-code platforms becomes a game-changer. By empowering existing manufacturing engineers to build and adapt their own digital tools, these platforms directly address the talent gap. This powerful combination of financial accessibility (cloud) and operational accessibility (low-code) is effectively democratizing advanced manufacturing intelligence. For small and medium-sized enterprises (SMEs), particularly in India’s burgeoning manufacturing sector, this represents a historic opportunity to leapfrog legacy technologies and compete on agility and innovation, not just scale.

Section 2: Why Traditional Manufacturing Execution System Is No longer Enough

To fully appreciate the revolutionary impact of AI, it is essential to first dissect the foundational weaknesses of the traditional MES paradigm. These limitations, once accepted as the cost of doing business, are now active impediments to competitiveness. They are not isolated flaws but interconnected issues that create a vicious cycle of inefficiency, high costs, and strategic inflexibility, making the case for an AI Manufacturing Execution System both urgent and compelling.

2.1 Limitation 1: Data Latency and Inaccuracy

The core function of a traditional MES is to create a system of record, yet the very process of data collection is often its greatest weakness. Many legacy systems rely on operators to manually enter production and quality data using paper forms, spreadsheets, or disconnected terminal applications. This method is inherently prone to human error, introducing inaccuracies and inconsistencies that corrupt the data at its source. Even when data collection is partially automated, it often occurs in batches at the end of a shift or a production run.

This creates significant data latency, meaning the MES provides a picture of what has already happened rather than what is happening now. It is a rear-view mirror, capable of reporting that a batch failed a quality check or that a critical machine went down, but only after the loss has been incurred and the damage is done. This reactive posture makes true, in-process optimization impossible. Decisions are based on lagging indicators, relegating the MES to a historical accounting tool rather than a real-time operational command center.

2.2 Limitation 2: Architectural Rigidity and Prohibitive Costs

Legacy MES solutions were often designed as monolithic, on-premise software suites. This architecture is notoriously inflexible, with hard-coded process configurations that are difficult and expensive to change. As per mastercontrol research article, implementing such a system is a massive undertaking, typically requiring 18 to 24 months from planning to go-live. The financial investment is equally daunting. Total project costs frequently start at $1 million to $2 million, with the cost of services (customization, integration, validation) often dwarfing the software license fees by a ratio of 2:1 for off-the-shelf systems and as high as 5:1 for custom-built toolkits.

This extreme cost and complexity create what is known as an “MES stall point”. The business case for such a large investment can often only be justified for a factory’s highest-volume or highest-margin production lines. As a result, the MES is deployed in isolated pockets, while the rest of the facility continues to run on paper and spreadsheets, creating a two-tiered operation and perpetuating data silos. Furthermore, the burden of customizing and re-validating these rigid systems for any process change discourages innovation and continuous improvement, effectively locking the manufacturer into outdated workflows.

2.3 Limitation 3: A System of Control, Not Optimization

At its core, a traditional MES is an enforcement engine. It is designed to ensure that operators follow pre-defined Standard Operating Procedures (SOPs), use the correct materials, and execute steps in the proper sequence. While this control is vital for maintaining baseline quality and consistency, the system itself has no inherent intelligence to analyze the effectiveness of that enforced workflow. It can confirm that a process was followed, but it cannot determine if that process was efficient or if a better alternative exists.

This limitation stems from its inability to connect and contextualize disparate data streams to uncover the root causes of problems. It may log a machine fault, a quality deviation, and a material shortage as separate events, but it lacks the analytical power to see the correlation between them. This failure to move from data collection to intelligent analysis means the system manages the status quo but does not actively drive optimization.

The compounding effect is clear: high costs and rigidity limit deployment, which reinforces data silos. Reliance on manual entry degrades data quality, which makes analytics unreliable. This lack of reliable analytics prevents true optimization, relegating the MES to a simple tracking tool and trapping the organization in a cycle of reactive problem-solving.

Traditional MES vs. AI-Powered MES: A Comparative Analysis

The following table starkly illustrates the paradigm shift from this traditional model to an intelligent, AI-powered future.

| Feature/Dimension | Traditional MES (The System of Record) | AI Manufacturing Execution System (The System of Intelligence) |

| Data Handling | Reactive Logging: Data is historical, often entered manually, and subject to delays. | Proactive Analysis: Data is captured automatically in real-time, contextualized, and analyzed for predictive patterns. |

| Decision Support | Static Reporting: Answers the question, “What happened?” | Prescriptive Guidance: Answers the question, “What should we do next?” |

| Maintenance Strategy | Preventive/Reactive: Maintenance is based on fixed schedules or occurs after a breakdown. | Predictive/Prescriptive: Maintenance is condition-based, triggered by AI forecasts of impending failures. |

| Quality Control | Post-Process Inspection: Relies on pass/fail checks at the end of the line, catching defects after the fact. | In-Process Prediction: Detects process anomalies and predicts quality deviations before defects occur. |

| Process Management | Workflow Enforcement: Rigidly follows a pre-defined, static plan. | Dynamic Optimization: Continuously analyzes performance to learn and suggest improvements to the plan. |

| User Interaction | Data Entry/Dashboards: Requires extensive training, is often complex, and relies on user input. | Conversational/Agentic: Allows natural language queries and AI-powered assistants to guide operators. |

| Architecture | Monolithic/On-Premise: Inflexible, high Total Cost of Ownership (TCO), and slow to scale. | Modular/Cloud-Native: Agile, scalable, with a faster time-to-value and lower barrier to entry. |

The true cost of clinging to a traditional MES is not merely its license and service fees; it is the immense opportunity cost of untapped efficiency, the material and financial waste generated by delayed problem-solving, and the strategic inflexibility imposed on a business that must adapt or perish.

An AI MES Software solution is designed to break this cycle by automating data capture, guaranteeing its quality, and embedding an intelligent, cognitive layer directly into the heart of production.

Section 3: Core Technologies of AI-Powered Manufacturing Execution System

An AI Manufacturing Execution System represents a fundamental architectural evolution. It moves beyond the traditional role of data collection and process enforcement to become a system of cognitive analysis, capable of understanding, predicting, and optimizing factory operations in real time. This transformation is driven by a suite of powerful, interconnected technologies that turn raw data into actionable intelligence.

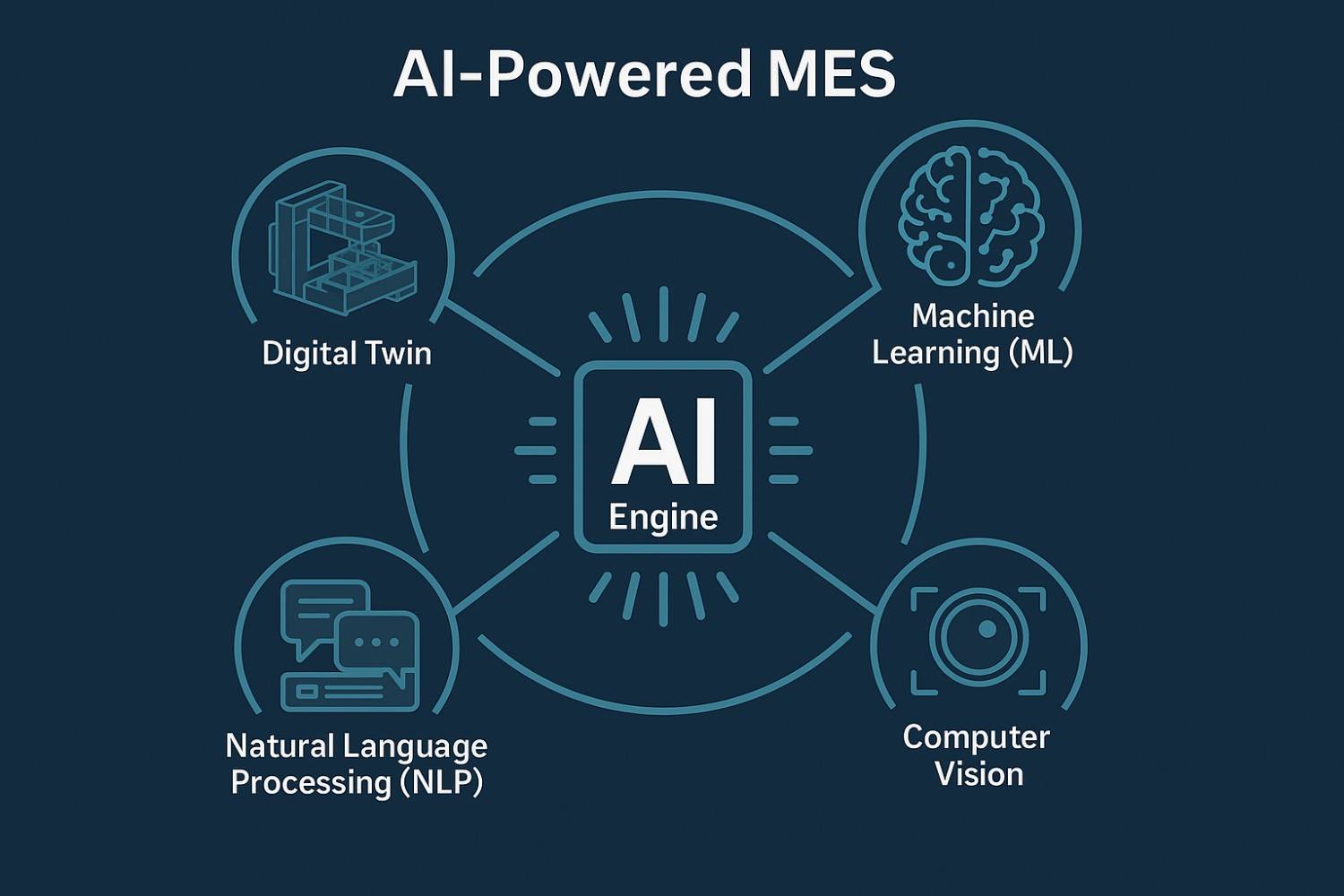

The Core AI Engine

At the heart of an AI MES Software platform are several key artificial intelligence technologies that work in concert:

- Machine Learning (ML): This is the foundational engine for all predictive capabilities. ML algorithms are trained on vast datasets of historical and real-time information sourced from the MES—including sensor readings, maintenance logs, quality measurements, and production run data. By analyzing these datasets, the algorithms can identify complex patterns and correlations that are invisible to human analysts, enabling them to predict future outcomes with a high degree of accuracy, such as the likelihood of an equipment failure or a deviation in product quality.

- Computer Vision: This technology gives the MES “eyes” on the factory floor. Using high-resolution cameras and sophisticated deep learning models, computer vision systems automate the process of visual inspection. They can identify microscopic defects on a fast-moving assembly line, verify correct component placement, or monitor work zones to ensure compliance with safety protocols, all with a speed and consistency that far surpasses human capabilities.

- Natural Language Processing (NLP): NLP makes the AI-powered MES more accessible and intuitive for the human workforce. It enables conversational AI interfaces, allowing an operator or manager to query the system using plain language, such as asking, “What was the first-pass yield for Line 3 on the night shift?” or “Show me all open maintenance orders for the CNC machines”. This technology also powers voice-activated controls, which can significantly improve efficiency and safety in hands-free operating environments.

Source – plantengineering

The Rise of the Digital Twin: The Factory’s Virtual Doppelgänger

One of the most powerful concepts enabled by the modern MES is the digital twin.

- Definition: A digital twin is far more than a static 3D model. It is a dynamic, virtual replica of a physical asset (like a machine), a process (like an assembly line), or even an entire factory. Its defining characteristic is that it is a living simulation, continuously fed with real-time data from a network of IoT sensors on its physical counterpart. This creates a bi-directional flow of information, allowing the virtual model to mirror the exact state of the real-world object at any given moment.

- AI’s Role: AI acts as the brain of the digital twin. It leverages the constant stream of real-time data to learn the behavior of the physical system. With this understanding, the AI can run countless “what-if” simulations within the virtual environment—testing a new production process, simulating the impact of a potential supply chain disruption, or optimizing equipment parameters—all without interrupting or risking live operations. Leading technology platforms like NVIDIA Omniverse are increasingly being used to build these photorealistic, AI-infused digital twins for industrial applications.

Generative AI: The Creative Force in Manufacturing

While traditional AI is primarily analytical, a new class of AI is emerging as a creative and generative force.

- Definition: Generative AI (GenAI) models, such as large language models (LLMs), do not just analyze existing data; they create new and original content. Based on the patterns and knowledge learned from their training data, they can generate text, images, code, or complex simulations.

- Key Applications in MES:

- Process Simulation and Scenario Modeling: GenAI can be tasked with creating thousands of plausible “what-if” scenarios to stress-test production plans. For example, it can simulate the cascading effects of a key supplier failing to deliver on time or a sudden spike in demand, allowing planners to identify vulnerabilities and build more resilient strategies.

- Synthetic Data Generation: A common challenge in training AI quality control models is the lack of data for rare but critical defects. GenAI can solve this by generating vast quantities of realistic “synthetic” defect data, enabling the training of more robust and accurate inspection models without having to wait for actual failures to occur.

- Automated Documentation and Work Instructions: The manual creation of documentation is a time-consuming and error-prone process. GenAI can automate this by generating complex compliance reports (e.g., for FDA or ISO standards), detailed standard operating procedures (SOPs), and even dynamic, role-specific work instructions, pulling the necessary data directly from the MES to ensure accuracy and consistency.

The power of these advanced AI models, particularly Generative AI, is directly proportional to the quality and context of the data they are trained on. A generic, public LLM has no inherent knowledge of a specific factory’s unique equipment, quality parameters, or production workflows. This is where the modern AI Manufacturing Execution System becomes indispensable. It serves as the single, authoritative source of truth for this rich, contextual data—encompassing real-time machine status, process parameters, material genealogy, quality measurements, and operator actions. This positions the MES not merely as another application in the factory’s tech stack, but as the foundational data layer—the veritable operating system—upon which manufacturing-specific AI and GenAI applications are built and executed.

Consequently, organizations that view AI as a standalone tool will likely see limited and frustrating returns. The true, transformative value is unlocked only when AI is deeply integrated with the MES, using its real-time data to generate highly relevant, context-aware, and immediately actionable outputs. This makes a robust, modern, and data-centric MES a non-negotiable prerequisite for any manufacturer serious about leveraging AI for competitive advantage.

Section 4:High-Impact AI Use Cases for the Modern Manufacturing Execution System

The theoretical capabilities of an AI Manufacturing Execution System translate into tangible, high-impact applications that are resolving some of the most persistent challenges on the factory floor. These use cases demonstrate a clear return on investment by driving unprecedented levels of efficiency, quality, and resilience.

Use Case 1: From Reactive Repairs to Proactive Resilience

- The Problem: Unplanned equipment downtime is one of the single largest sources of lost productivity and revenue in manufacturing. It disrupts schedules, delays customer orders, and leads to costly emergency repairs.

- The AI-MES Solution: Instead of waiting for a machine to fail, an AI-powered MES uses predictive maintenance to anticipate failures before they occur. Machine learning algorithms continuously analyze real-time data from IoT sensors—monitoring variables like vibration, temperature, and power consumption—along with historical maintenance logs stored within the MES. By detecting subtle anomalies and patterns that precede a breakdown, the system can predict a future failure with a high degree of confidence. The MES then automatically generates a work order and schedules the maintenance activity during a planned shutdown, optimizing the use of maintenance staff and spare parts.

- Real-World ROI: The results are dramatic. As per International Journal of Scientific Research Studies, it shows that AI-integrated MES can reduce unplanned downtime by up to 41%. Research by McKinsey corroborates these findings, noting that AI-powered predictive maintenance can decrease machine downtime by as much as 50% and extend the operational life of equipment by up to 40%. Case studies provide further proof: a 20% reduction in overall maintenance costs has been observed in some implementations , and Johnson & Johnson’s Indian operations successfully used machine learning to cut unplanned downtime by 50% per Deloitte.

Use Case 2: Achieving Zero-Defect Manufacturing

- The Problem: Manual quality inspection is inherently limited by human factors like fatigue, inconsistency, and the inability to detect microscopic defects at high speed. This leads to quality escapes, customer returns, and expensive rework.

- The AI-MES Solution: AI-powered computer vision systems, integrated directly with the MES, serve as tireless, hyper-accurate inspectors on the production line. These systems use cameras and deep learning models to analyze every product in real time, identifying defects, misalignments, or cosmetic flaws with a precision that is impossible for the human eye to match. Crucially, the system does more than just flag a defective part. It automatically logs the defect, the exact time, the machine involved, and all relevant process parameters directly into the MES, creating a complete, traceable record that is invaluable for immediate root cause analysis.

- Real-World ROI: The impact on quality is significant. Research indicates that AI-enhanced inspection models can achieve up to 95% accuracy in defect detection. A French aerospace manufacturer implementing an AI-driven quality system saw a 15% decrease in its overall defect rates. Across various industries, the integration of AI with MES has led to a documented 32% improvement in first-pass yield—the percentage of products manufactured correctly the first time without needing rework per Research gate.

Use Case 3: Dynamic Production Scheduling & Optimization

- The Problem: Traditional production schedules, often created in spreadsheets or legacy systems, are static and brittle. They are rendered obsolete the moment an unexpected event occurs—a machine breakdown, a critical raw material delay, or the arrival of an urgent, high-priority customer order. Manually recalculating and re-optimizing these schedules is a slow, complex, and often sub-optimal process.

- The AI-MES Solution: An AI MES Software platform transforms scheduling from a static, periodic task into a dynamic, continuous optimization process. The system ingests a constant stream of real-time data from across the factory—machine availability, current work-in-progress (WIP), material inventory levels, labor availability, and new order priorities. AI algorithms then process these variables against defined business objectives (e.g., minimize production cost, maximize on-time-in-full delivery, reduce equipment changeover times) to constantly generate the most optimal production schedule.

- Real-World ROI: The efficiency gains are substantial. A global food manufacturer that implemented C3 AI’s production scheduling solution was able to reduce the time required to generate complex schedules by 96%, while also identifying $1.5 million in annual savings from reduced changeover times at a single facility. In another case, Cipla India used an AI-powered scheduler to achieve a 22% reduction in changeover times. Academic research using genetic algorithms has demonstrated the potential to optimize production line sequencing by as much as 42%.

Use Case 4: Generative AI on the Factory Floor

- The Problem: The manufacturing sector faces a critical skills gap, with experienced workers retiring and new hires requiring extensive training. A vast amount of critical “tribal knowledge” about how to run and troubleshoot machinery exists only in the minds of veteran operators and is often poorly documented.

- The GenAI-MES Solution: Generative AI, trained on the specific data within an MES, can help codify and democratize this expertise.

- Interactive Work Instructions: Instead of relying on static, paper-based manuals or PDFs, GenAI can generate dynamic, step-by-step digital work instructions. These instructions can be tailored to the specific product variant being assembled and can even adapt to the operator’s measured skill level, providing more detail for novices and a streamlined view for experts.

- Conversational Troubleshooting: When an operator encounters an alarm or an issue, they can interact with a GenAI-powered assistant in natural language. By asking, “What does alarm code 502 mean on this machine?” the operator can receive immediate, contextual guidance drawn from technical manuals, historical maintenance logs from the MES, and best-practice repair procedures.

- Automated Reporting: GenAI can automate the tedious task of compiling reports. A quality manager could simply request, “Generate a summary of all non-conformance reports for product XYZ from the last quarter,” and the system would pull the relevant data directly from the MES and synthesize it into a formatted report.

These high-impact use cases are not isolated silos of value; they are deeply interconnected components of a larger, intelligent system. Their integration within a single AI Manufacturing Execution System platform creates a powerful, compounding value loop.

For instance, the intelligent quality control system detects a recurring microscopic flaw in a product. This quality data, logged in the MES, is immediately available to the predictive maintenance algorithm. The algorithm analyzes this data alongside real-time sensor data from the production line and identifies a correlation: the defect only appears when a specific machine exhibits a particular vibration signature, indicating degrading performance. It proactively flags the machine for maintenance. The dynamic scheduling system is automatically alerted to this upcoming maintenance event and instantly re-optimizes the entire factory’s production schedule to work around the planned downtime, rerouting jobs to other lines to minimize any impact on customer delivery dates. Simultaneously, a generative AI assistant uses the MES data to create a highly specific troubleshooting guide for the maintenance technician, highlighting the known correlation between the vibration signature and the quality defect, thereby accelerating the diagnosis and repair.

This seamless flow of intelligence—from quality to maintenance to scheduling to human assistance—creates a virtuous cycle where each component makes the others more effective. This demonstrates that the total return on investment from a holistic, integrated platform approach is far greater than the sum of its individual parts.

Section 5: A Strategic Roadmap to Implement AI MES

As technology consultants at Softlabs Group, we understand that acquiring the right AI MES Software is only the beginning of the journey. The path to successful adoption and realizing tangible value is paved with significant challenges related to data, people, legacy systems, and security. A staggering 42% of AI initiatives are expected to be abandoned in 2025, not because the technology failed, but because they failed to scale from a controlled pilot to full production. A strategic, holistic roadmap is therefore not just advisable; it is essential for success.

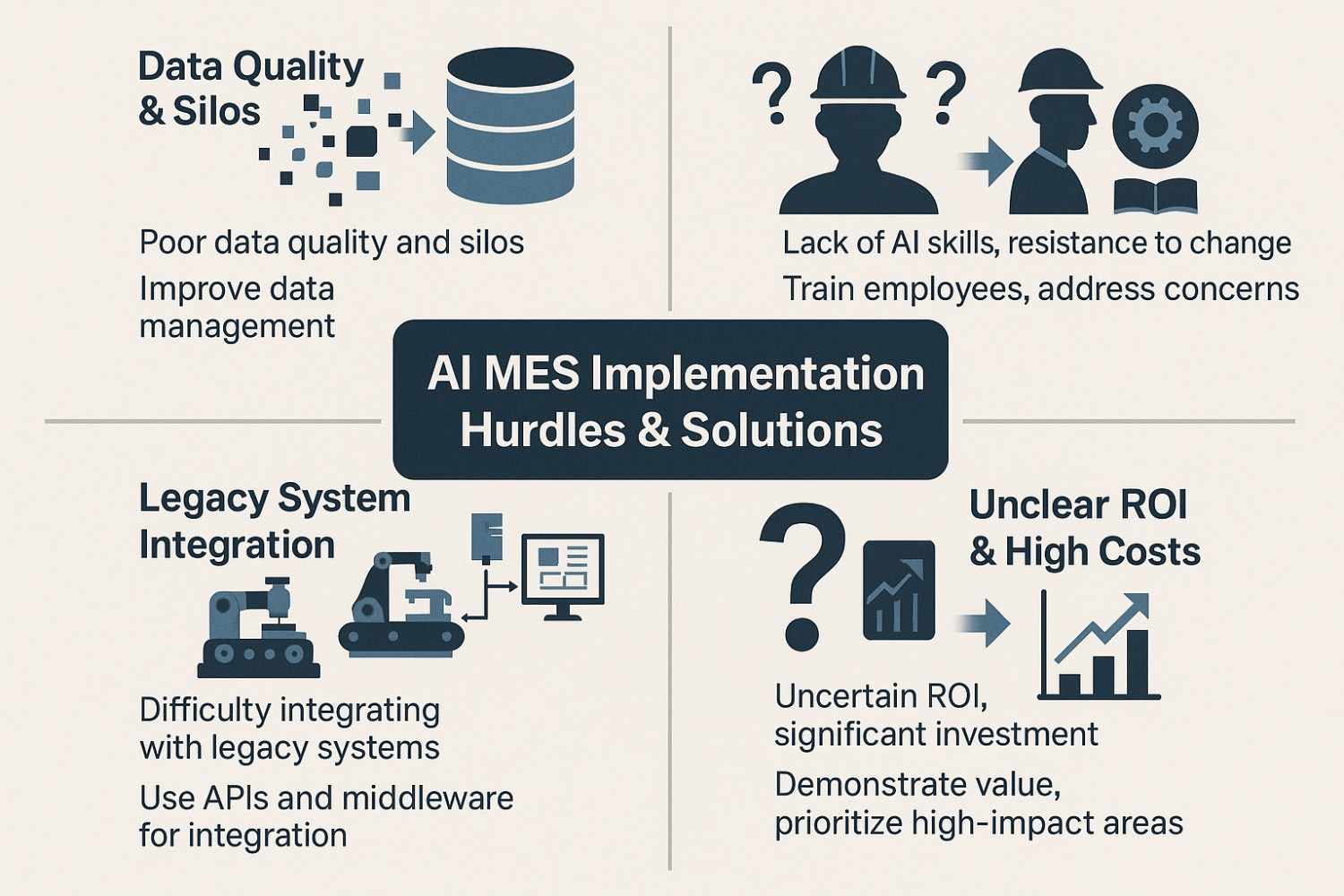

Step 1: Overcoming the Implementation Hurdles

Successfully deploying an AI Manufacturing Execution System requires proactively addressing the most common points of failure.

- Challenge: Data Quality & Silos. This is the number one obstacle to any successful AI implementation. AI models are fundamentally dependent on the data they are trained on—a principle often summarized as “garbage-in, garbage-out.” A recent survey found that nearly 70% of manufacturers identify problems with data quality, contextualization, and validation as the most significant barrier to AI adoption, with 47% citing data fragmentation as a major impediment.

- Solution: The journey must begin with a thorough data readiness assessment. This involves creating a unified data strategy that focuses on cleansing, standardizing, and integrating data from disparate sources. A key technical step is to break down the silos between Information Technology (IT) systems (like ERP) and Operational Technology (OT) systems (like PLCs and SCADA) using modern, open communication standards such as OPC UA and MQTT. This creates the unified, high-quality data foundation upon which AI models can be reliably built.

- Challenge: The Skills Gap & Workforce Resistance. Technology alone cannot drive transformation. The World Economic Forum estimates that 54% of manufacturing workers will require significant upskilling by 2025 to adapt to an AI-driven environment. Compounding this is a natural human resistance to change, often fueled by fears of job replacement.

- Solution: The strategic narrative must be one of empowerment, not replacement. AI should be framed as an intelligent “co-pilot” that augments human skills, automates tedious tasks, and allows workers to focus on more complex, value-adding activities. Investment in training is critical, but it must be role-specific. Manufacturing engineers need to understand what AI can and cannot do, not the intricacies of building neural networks. Maintenance managers need to grasp the applications of predictive analytics, not the underlying algorithms. For immediate needs, partnering with an expert consulting firm like Softlabs Group can bridge the talent gap during the crucial implementation and initial operational phases.

- Challenge: Legacy System Integration. A significant portion of the manufacturing sector—an estimated 65%—still relies on legacy equipment and systems that were not designed for modern connectivity and are often incompatible with AI technologies.

- Solution: A full “rip and replace” strategy is often financially and operationally unfeasible. The more pragmatic approach is to prioritize MES solutions that offer robust, API-based integration capabilities, allowing them to communicate with and extract data from older systems. A carefully planned, phased migration strategy—whether a “Big Bang” switchover for simpler environments, a “Phased Introduction” by production line, or running “Parallel Systems” for a period in highly critical settings—can effectively manage the risk, cost, and disruption of the transition.

- Challenge: Unclear ROI & High Costs. The significant upfront investment and the perceived difficulty in quantifying the return on investment (ROI) are major sources of hesitation, preventing 40-43% of manufacturers from pursuing AI integration per supply chain brain.

- Solution: Avoid broad, unfocused AI initiatives. Instead, start with a few targeted use cases that address clear, existing pain points and have a direct, measurable payback potential, such as reducing unplanned downtime on a critical production line or improving the first-pass yield of a high-value product. Building a robust business case with quantifiable metrics and credible industry benchmarks is essential for securing executive buy-in.

Step 2: Fortifying the Smart Factory – A Modern Approach to Cybersecurity

The very connectivity that makes an AI Manufacturing Execution System so powerful also makes it a prime target for cyber threats. The deep integration of IT and OT systems creates a vast new attack surface, where a digital breach can have immediate and catastrophic physical consequences, such as halting production, damaging expensive equipment, or compromising product integrity. Cybersecurity is therefore a foundational pillar of any smart factory initiative.

A fundamental challenge in securing the smart factory is bridging the historical divide between IT and OT teams. These two domains have traditionally operated with different priorities and cultures. IT security emphasizes the “CIA triad”—Confidentiality, Integrity, and Availability—often prioritizing the protection of data (confidentiality) above all else. In contrast, OT teams prioritize Availability and Safety above everything; their primary mandate is to keep the production lines running continuously and safely. This can lead to conflict: an IT team might insist on patching a system, which requires downtime, while the OT team resists any action that could interrupt production.

Attackers are adept at exploiting this seam. They can breach the corporate IT network and move laterally to the less-defended OT environment, or directly target OT systems that often lack modern security controls. The potential to cause physical disruption makes manufacturing an attractive target for ransomware attacks, as companies are more likely to pay to restore operations. A successful AI MES deployment is therefore impossible without a unified cybersecurity strategy that bridges this IT/OT gap. This requires establishing a joint governance program that respects the priorities of both worlds and implementing a multi-layered, defense-in-depth security architecture.

Key strategies include:

- Network Segmentation: This is a foundational control. Critical OT networks must be logically or physically isolated from the corporate IT network and the public internet using firewalls and other access controls. This segmentation limits the “blast radius” of an attack, preventing an intruder who has compromised an IT system from easily moving into the operational environment.

- Zero-Trust Architecture: The principle of Zero Trust dictates that no user, device, or application should be inherently trusted, regardless of its location on the network. Every access request must be strictly authenticated and authorized before being granted. This approach is critical in a converged IT/OT environment, ensuring that trust is never assumed.

- AI for Threat Detection: The best defense against AI-driven attacks is to use AI for defense. Modern security systems leverage AI and machine learning to monitor network traffic for anomalous behavior. These systems can detect subtle patterns indicative of a sophisticated attack—such as a PLC issuing unusual commands or a slight change in data flow that precedes sabotage—that would be missed by traditional, signature-based security tools.

- Adherence to Standards: Implementing a security framework based on established industry standards, such as IEC 62443 for Industrial Automation and Control Systems, provides a structured and proven methodology for securing the smart factory.

Source – cloud ranger cyber

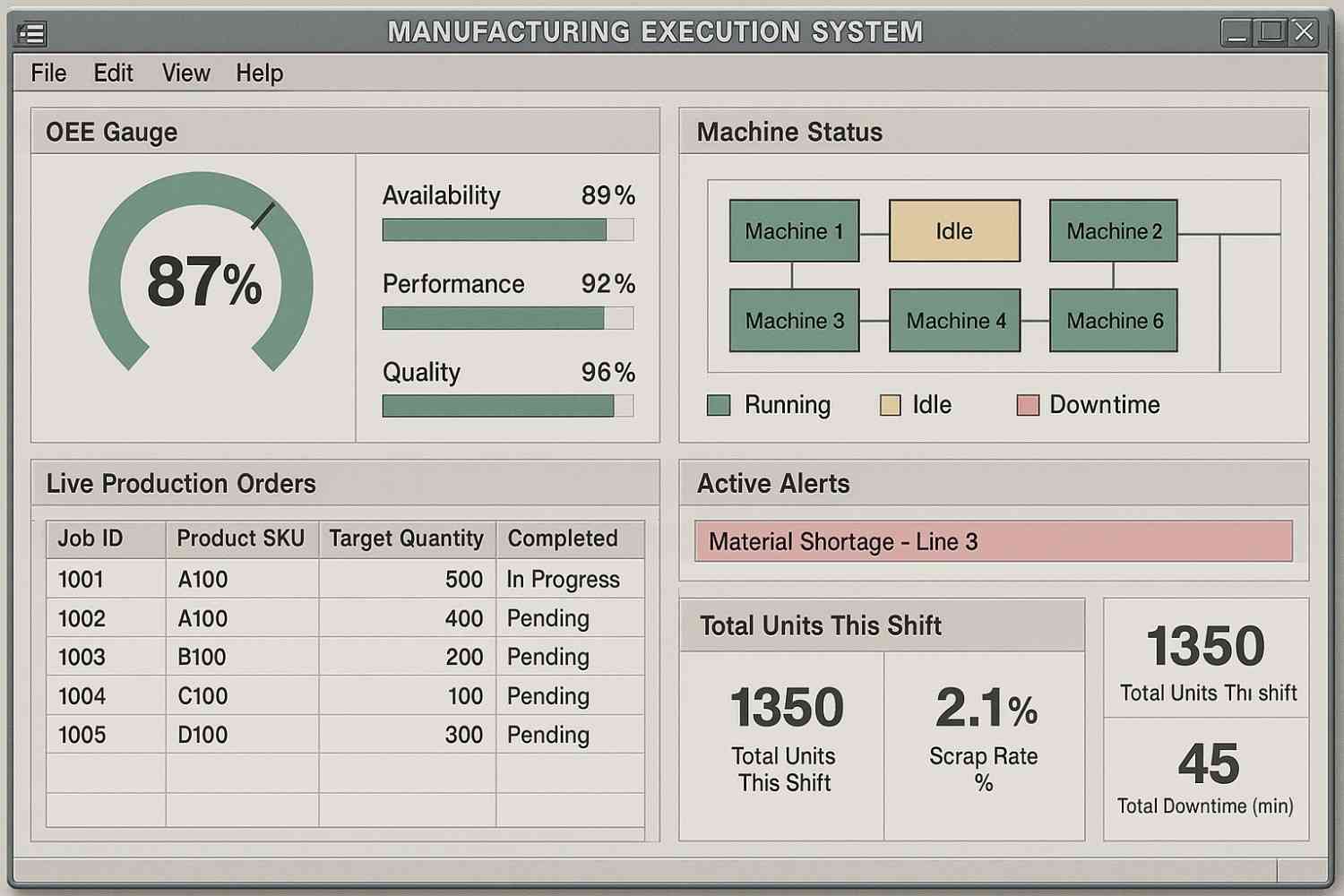

Step 3: Quantifying the ROI of Your AI MES Investment

To move an AI initiative from a promising pilot to a fully-funded, enterprise-wide deployment, a clear and compelling business case is essential. The focus must be on measuring tangible business outcomes—such as reduced cost per unit, increased Overall Equipment Effectiveness (OEE), or improved on-time delivery—not just on technical milestones. Structured methodologies, such as the NIST AI Risk Management Framework, can provide a valuable guide for governing, mapping, and measuring AI projects to ensure they remain aligned with strategic business goals. The following table summarizes some of the quantifiable ROI metrics documented in recent industry case studies and research.

Table 2: Quantifiable ROI from AI in MES Implementations

| AI Application Area | Key Performance Metric | Quantifiable Improvement | Source / Case Study |

| Predictive Maintenance | Unplanned Downtime | Up to 50% Reduction | McKinsey & Company |

| Maintenance Costs | 10% to 40% Reduction | The Research Insights | |

| Equipment Uptime | 20% Increase | ResearchGate Study | |

| Intelligent Quality Control | First-Pass Yield | 32% Improvement | International Journal of Scientific Research |

| Defect Rates | 15% Decrease | French Aerospace Manufacturer | |

| Scrap Rates | 20% to 30% Reduction | The Research Insights | |

| Production Scheduling | Time to Generate Schedules | 96% Reduction | C3 AI / Global Food Manufacturer |

| Changeover Times | 22% Reduction | Cipla India | |

| Production Line Optimization | Up to 42% Improvement | Genetic Algorithm Study | |

| Supply Chain & Inventory | Inventory Levels | 10% Reduction | UK Food Manufacturer |

| Logistics Costs | 15% Reduction | Softlabs Group / McKinsey | |

| Overall Labor Productivity | Labor Productivity | 15% to 30% Improvement | Softlabs Group / Industry Data |

Section 6: The Future is Autonomous: What’s Next for Manufacturing?

The current wave of AI integration is not the end-state but rather a crucial phase in a longer evolutionary trajectory. The convergence of AI, IoT, and the Manufacturing Execution System is laying the groundwork for a future where factories are not just “smart” but increasingly autonomous, self-optimizing, and resilient.

The Trajectory to Smart Factories

The “smart factory” concept, once a distant vision, is rapidly becoming the industry standard. As more manufacturers adopt these technologies, their operations will be increasingly defined by a new set of capabilities :

- Real-time, Self-Optimizing Processes: The future MES will function as a closed-loop control system for the entire factory. AI algorithms will not only predict issues but will also automatically adjust process parameters—such as machine speed, temperature, or material flow—in real time to maintain optimal efficiency and quality, often without any need for human intervention.

- Increased Automation & “Lights-Out” Operations: As AI-driven robotics and automation systems become more sophisticated, they will be capable of handling an ever-wider range of complex assembly, handling, and inspection tasks. This will accelerate the trend toward “lights-out” manufacturing, where factories can operate around the clock with minimal human supervision, leading to dramatic increases in production speed and asset utilization.

The Rise of AI Agents

The next frontier in this evolution is the emergence of “AI agents.” These are advanced AI systems that can not only analyze and predict but also reason, plan, and execute actions autonomously to achieve high-level goals. This is a significant step beyond current AI applications. In a manufacturing context, a future AI agent could be tasked with managing an entire supply chain. It could autonomously negotiate pricing and delivery schedules with the AI agents of suppliers, re-allocate production schedules across a global network of factories in response to a geopolitical disruption, and optimize logistics and shipping routes, all without direct human command. The interest in this technology is already high, with surveys showing that two-thirds of companies are already exploring the use of AI agents.

Sustainability and Green Manufacturing

AI will be a critical enabler for the growing imperative of sustainable manufacturing. An AI-driven MES contributes directly to environmental goals in several ways: it optimizes energy consumption across the plant by analyzing usage patterns and shutting down non-essential equipment; it minimizes material waste through more precise production and higher first-pass quality; and it reduces the carbon footprint of logistics by optimizing delivery routes and truckloads. This synergy allows manufacturers to achieve sustainability targets while simultaneously reducing operational costs.

Mass Customization at Scale

Finally, AI is set to resolve one of the longest-standing trade-offs in manufacturing: the conflict between customization and efficiency. In the past, offering personalized products meant sacrificing the economies of scale that come with mass production. AI changes this equation. An AI Manufacturing Execution System can automatically generate the specific machine instructions and adjust production line configurations on the fly to handle a high mix of personalized, on-demand orders. This will enable manufacturers to efficiently cater to individual customer preferences, unlocking new markets and business models without compromising production speed or cost-effectiveness.

Conclusion: Your Partner in the Digital Transformation Journey

The evidence is conclusive. The Manufacturing Execution System is undergoing its most significant transformation in decades, evolving from a passive system of record into the intelligent, AI-powered command center of the modern factory. This is no longer a matter of “if,” but “when and how.” For manufacturing leaders, the journey toward adopting an AI Manufacturing Execution System is a strategic imperative for securing long-term competitiveness, resilience, and profitability.

However, as this report has detailed, the path is not without its complexities. It is a journey that requires navigating significant challenges in technology selection, data strategy, workforce development, and cybersecurity. Success demands more than simply purchasing a software license; it requires a deep understanding of the manufacturing domain, a clear strategic vision, and a partnership with experts who can guide the implementation process from start to finish.

This is the precise value that we at Softlabs Group provide. With over two decades of global experience and a strong foundation in Mumbai, we specialize in this critical intersection of custom software development, advanced AI/ML integration, and deep manufacturing industry expertise. We are not just a technology vendor; we are a strategic partner committed to your success. We work alongside your teams to:

- Develop a clear, pragmatic AI strategy and implementation roadmap tailored to your specific business goals and operational realities.

- Customize, develop, and integrate AI MES solutions that work seamlessly within your unique technological and process environment.

- Establish robust data governance and cybersecurity frameworks to protect your critical operations and intellectual property.

- Train and empower your workforce, ensuring they have the skills and confidence to leverage these new tools to their full potential.

The next industrial revolution is not on the horizon; it is here. The manufacturers who thrive will be those who embrace this change with a clear strategy and the right partners.

Contact Softlabs Group today to schedule a consultation !