Executive Summary: The Next Frontier of Cement Plant Efficiency

Cement producers operate in a market defined by intense pressure on operational margins. While significant investments in modernizing plants have improved efficiency, many facilities have reached the ceiling of what traditional automation can achieve. The next leap in profitability and sustainability for the AI in cement industry comes from a new generation of intelligent systems.

Practical AI in cement manufacturing provides a path to transcend the limits of conventional control. It offers solutions for the industry’s most pressing challenges, from kiln energy consumption and unplanned downtime to product quality and logistics. This technology introduces an adaptive intelligence layer over existing infrastructure.

This layer helps plants move from reactive problem-solving to proactive, predictive optimization, unlocking significant value. The strategic role of AI in cement manufacturing is to deliver a more stable, reliable, and cost-effective operation.

1. The Challenge: Hitting the Ceiling of Traditional Cement Plant Automation

Context: The Modern Cement Manufacturing Landscape

The cement industry is fundamentally capital-intensive, requiring huge initial investments in land and machinery. Operations are defined by two relentless pressures: volatile energy and fuel prices, and increasing regulatory scrutiny over environmental impact. Cement production is a highly energy-intensive process and a significant source of global CO2 emissions. This dual pressure makes operational efficiency not just a competitive advantage but a core requirement for sustainable and profitable operation. The effective use of AI in cement manufacturing directly addresses these core pressures.

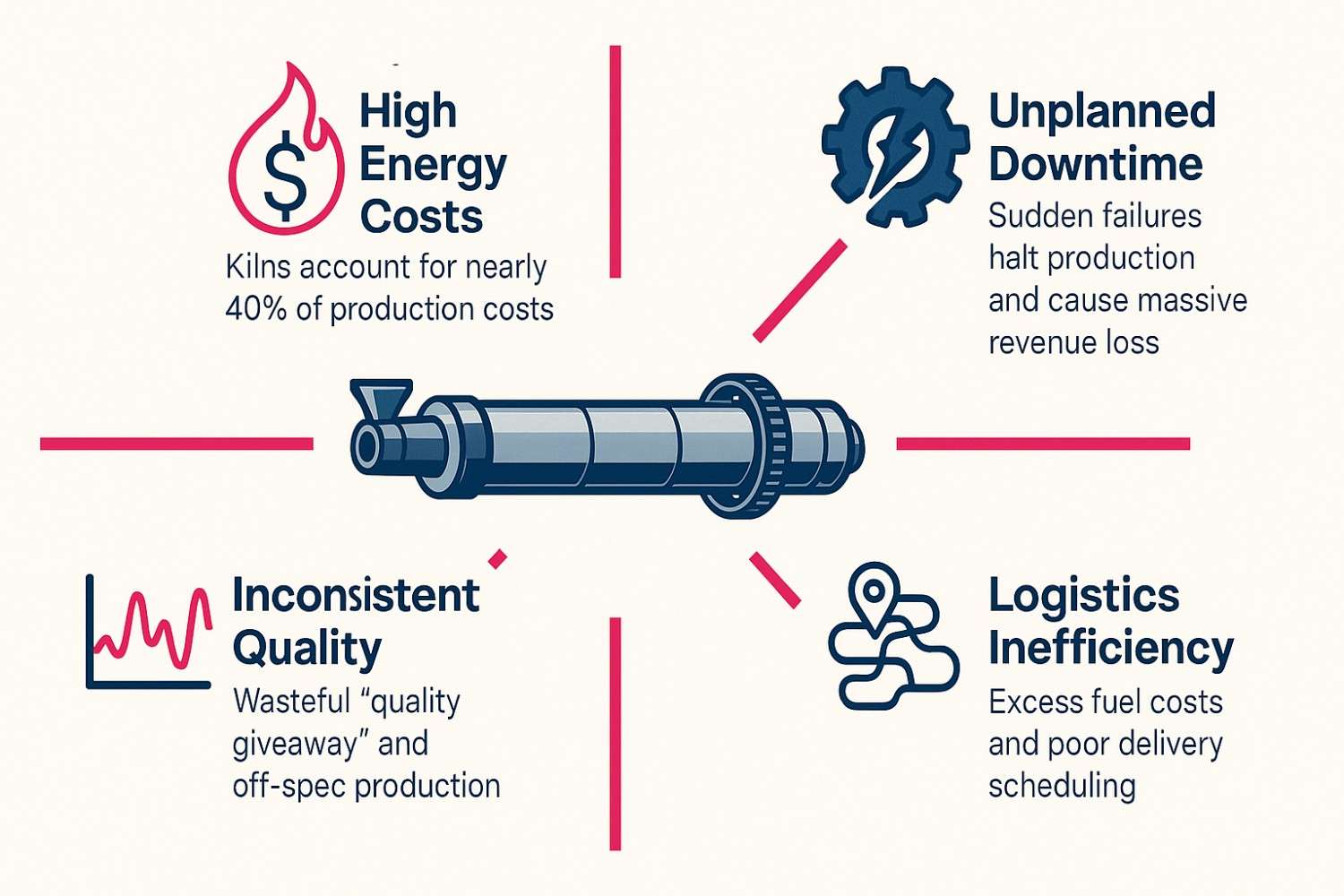

Key Pain Points Addressed by AI

- Crippling Kiln Energy Costs: Pyro-processing kilns represent the single largest operational expense, often accounting for nearly 40% of production costs.(https://www.mdpi.com/2673-4591/67/1/11). A primary source of this inefficiency stems from operators using “safety buffers”—intentionally running kilns hotter than theoretically necessary to guarantee clinker quality, a practice known as overburning. This common practice wastes enormous amounts of fuel.

- Catastrophic Unplanned Downtime: An unexpected equipment failure, such as a gearbox in a primary grinding mill, can halt production for days. This results in massive revenue loss and expensive emergency repairs. Across industries, a single hour of unplanned downtime can cost an organization more than $100,000, with industrial manufacturers spending an estimated $50 billion annually to address it. The core problem is that traditional maintenance schedules are based on fixed intervals, which fail to prevent sudden, catastrophic breakdowns.

- Inconsistent Product Quality & Waste: Maintaining consistent clinker quality is a constant challenge. To avoid producing sub-par material, operators often engage in “quality giveaway”—producing cement at a quality level far above specifications, which wastes both energy and raw materials. Furthermore, the significant time lag for traditional lab-based quality tests means a plant can produce a large volume of off-spec clinker before a deviation is even detected and corrected.

- Complex and Inefficient Logistics: Inefficiencies extend beyond the plant floor into the supply chain. Cement producers often struggle with optimizing truck routes, which leads to excess fuel consumption and costly delivery delays. Manual processes for tracking shipments and billing can also create frequent disputes, impacting cash flow and customer satisfaction. The automation in cement industry has not yet fully streamlined these complex logistical webs.

Limitations of Traditional Approaches

Traditional control systems, such as a Distributed Control System (DCS) (a process control system for a plant or process) or a Programmable Logic Controller (PLC) (a ruggedized digital computer adapted for the control of manufacturing processes), are excellent at executing pre-defined, static rules. They can maintain a setpoint with high reliability.

However, they have reached their operational limits. They cannot effectively manage the dynamic, unstable, and highly interactive nature of chemical processes like cement production.

These systems cannot predict future states or understand the complex, non-linear relationships between thousands of variables in a kiln. They cannot learn from past performance to adapt their strategy. They operate based on fixed rules and cannot see the “whole picture” of the process.

The four pain points are not isolated issues. They are interconnected symptoms of this single, systemic inability to manage process variability in real-time. For instance, running kilns hot to ensure quality wastes fuel and accelerates equipment wear. This in turn increases the risk of downtime.

A truly transformative solution must address this root cause. This is where AI in cement manufacturing provides its greatest value.

2. The AI Solution Concept: The Intelligent Cement Plant Optimization System

To overcome these challenges, we envision a unified AI platform with specialized modules, not just a collection of separate tools. This “Intelligent Cement Plant Optimization System” acts as a digital layer that integrates with and enhances existing plant infrastructure. The vision for AI in a cement plant is to create a self-learning, self-optimizing operation. The following table outlines how this conceptual system directly addresses the industry’s core pain points.

| Core Pain Point | Limitation of Traditional Method | AI Solution Approach |

|---|---|---|

| Kiln Energy Inefficiency | Fixed setpoints; operator “safety buffers” leading to over-burning fuel. | Model Predictive Control (MPC) and Reinforcement Learning (RL) to dynamically optimize fuel/air mix in real-time. |

| Unplanned Downtime | Reactive, time-based maintenance schedules that miss developing faults. | Time-Series Anomaly Detection on IoT sensor data (vibration, temp) to predict failures weeks in advance. |

| Inconsistent Quality | Long lag times for lab-based quality tests, leading to off-spec production. | Computer Vision and Machine Learning to predict clinker quality (e.g., free lime) from real-time process data. |

| Logistics Inefficiency | Manual dispatching and static routing, leading to excess fuel use and delays. | AI-driven Optimization for demand forecasting, inventory management, and dynamic vehicle routing. |

Vision & Objectives for an AI-Powered System

The ultimate vision is to create a self-learning digital twin of the plant that continuously maximizes efficiency, reliability, and quality. The practical objectives of such a system are clear and directly counter the key pain points. The goal of using AI in cement manufacturing is to achieve measurable results.

- Minimize kiln fuel consumption and CO2 emissions by dynamically adjusting control parameters in real-time.

- Eliminate unplanned downtime by predicting critical equipment failures weeks or even months in advance.

- Maximize the production of on-spec clinker by predicting quality metrics in real-time, which reduces giveaway and waste.

- Streamline the entire supply chain by optimizing inventory, dispatch, and delivery routes for maximum efficiency.

3. How It Works: The Technology Explained

This section explains how AI is being used in cement industry operations to achieve these objectives. The technology transforms raw data into actionable intelligence that empowers operators and managers.

Data Acquisition: Tapping into the Plant’s Digital Nervous System

An advanced AI system does not require a complete overhaul of a plant’s existing control infrastructure. Instead, it intelligently integrates with it. The process begins with data acquisition. The system taps into the plant’s digital nervous system. It pulls vast amounts of historical and real-time data from existing DCS and Supervisory Control and Data Acquisition (SCADA) (a system for remote monitoring and control that operates with coded signals over communication channels).

The system also uses plant data historians. For critical assets where crucial sensor data is missing, such as vibration or acoustic data on a gearbox or grinding mill, low-cost Internet of Things (IoT) (a network of physical objects embedded with sensors and software) sensors can be added (https://www.birlasoft.com/articles/ai-iot-cement-supply-chain) to fill these data gaps. This creates a comprehensive dataset covering every aspect of the operation.

AI-Powered Solutions for Core Challenges

Instead of a single, generic process, the Intelligent Cement Plant Optimization System uses specialized modules. Each module is tailored to solve one of the core operational challenges by following a clear data-to-outcome process.

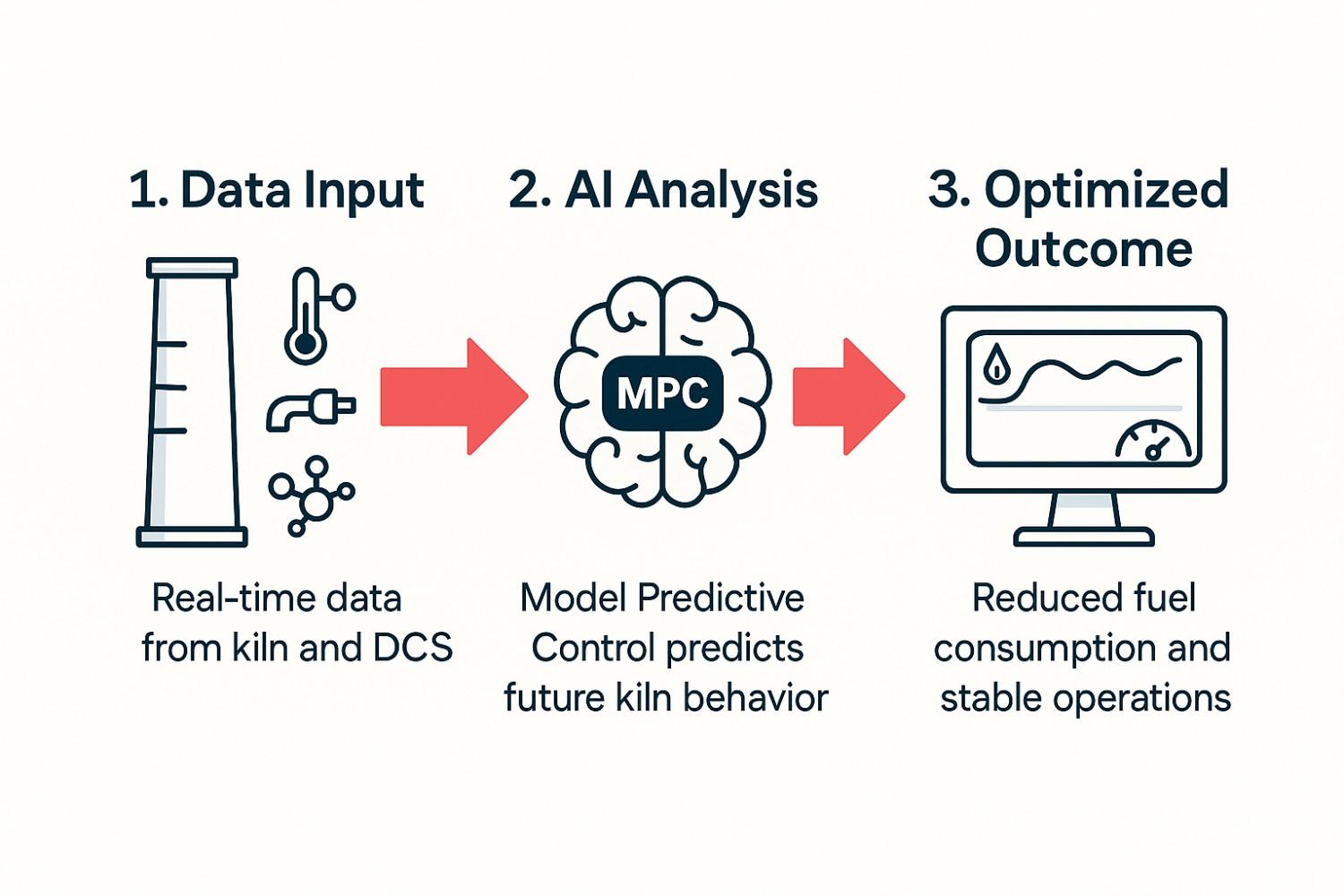

Solution 1: Kiln Energy Optimization

This solution directly targets the high fuel costs associated with the pyro-processing kiln. Here’s how it works:

- Data Input: The system ingests thousands of real-time variables from the DCS, including kiln temperature profiles, fuel flow rates, fan speeds, and raw meal chemistry.

- AI Analysis: A Model Predictive Control (MPC) model analyzes these complex interactions to predict how the kiln will behave in the near future. It understands the delayed and interconnected effects of every adjustment.

- Intelligent Action: Based on its predictions, the AI calculates the most efficient setpoints for fuel and air to maintain optimal combustion.

- Outcome: The system provides operators with these optimized recommendations, eliminating wasteful “safety buffers” and ensuring the kiln operates at peak thermal efficiency, thereby reducing fuel consumption and CO2 emissions.

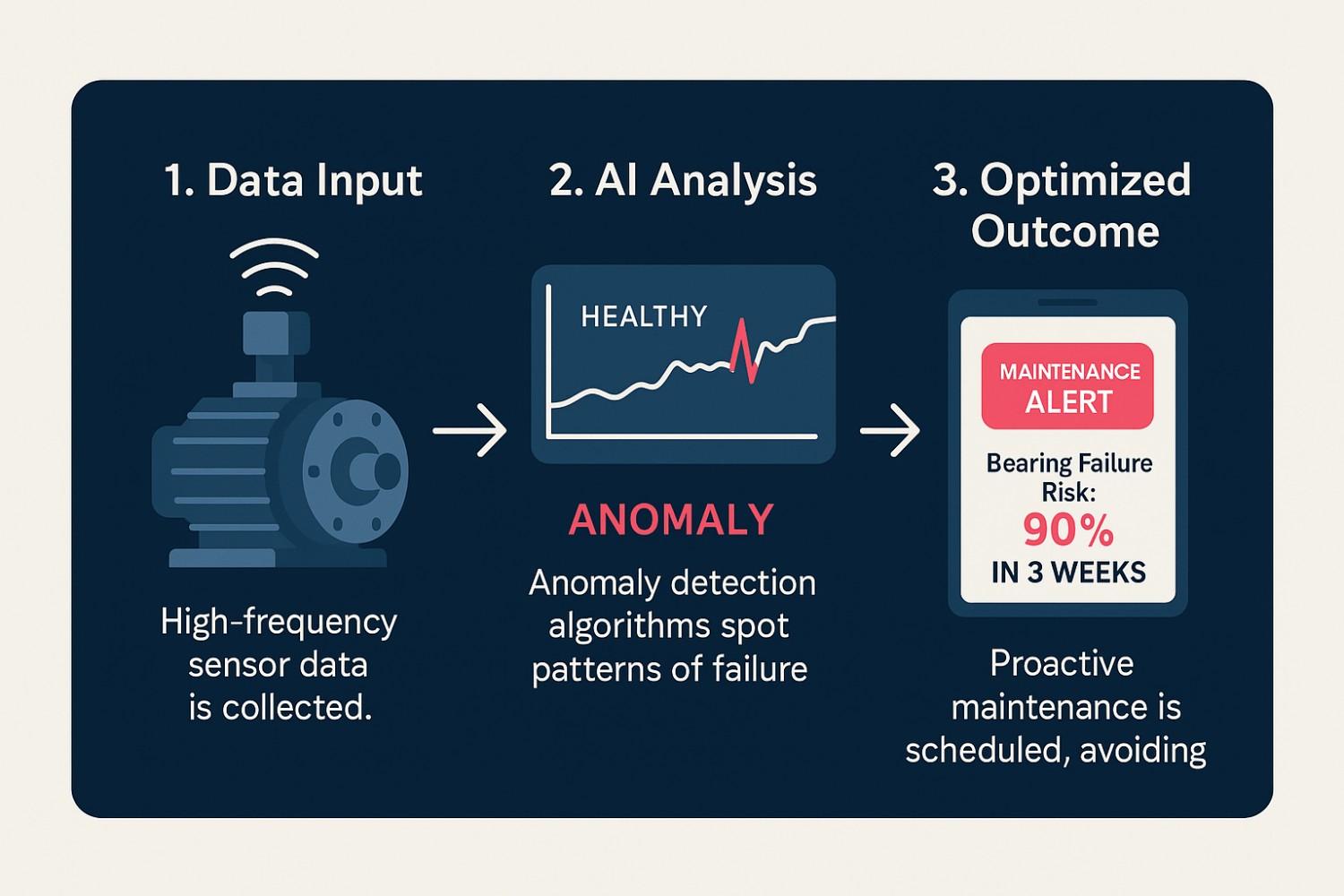

Solution 2: Predictive Maintenance for Critical Assets

This solution prevents costly unplanned downtime by shifting from a reactive to a predictive maintenance culture.

- Data Input: It uses data from specialized IoT sensors installed on critical machinery like grinding mills and gearboxes, capturing high-frequency vibration, temperature, and acoustic data.

- AI Analysis: A time-series anomaly detection model is trained on this data to learn the unique “healthy” signature of each machine. It continuously monitors the live data stream for subtle deviations from this normal pattern.

- Intelligent Action: When the model detects a pattern that signals a developing fault (e.g., a bearing failure), it issues a predictive alert.

- Outcome: Maintenance teams receive a warning weeks or even months in advance, along with diagnostic insights. This allows them to schedule repairs during planned downtime, preventing catastrophic failures and massive production losses.

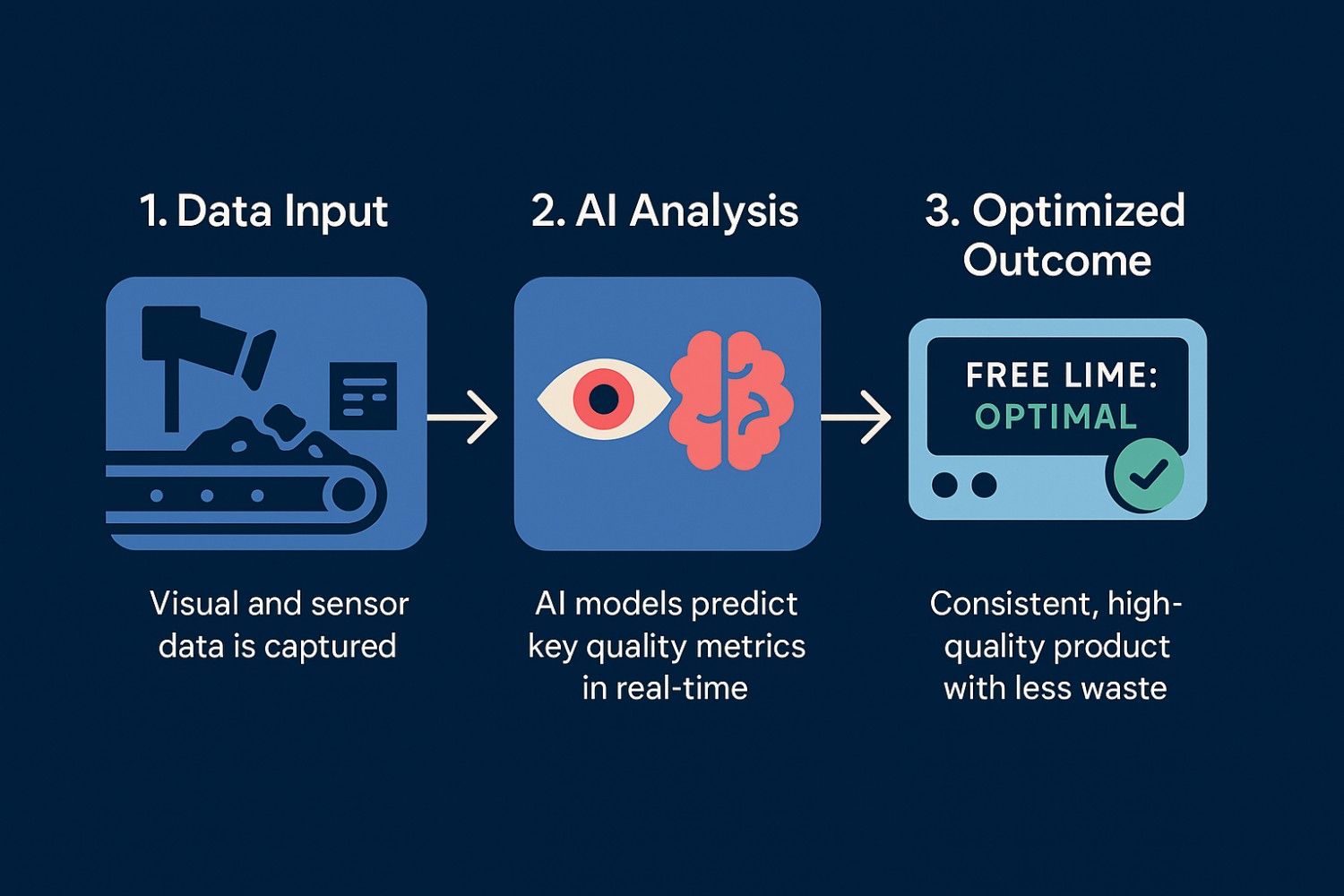

Solution 3: Real-Time Product Quality Control

This solution eliminates inconsistent quality and waste by providing instant feedback on clinker production.

- Data Input: The system uses two data streams: real-time camera feeds of the clinker on the conveyor and process data (like burning zone temperature and gas composition) from the DCS.

- AI Analysis: A Computer Vision model analyzes the clinker images to assess properties like nodule size and color. Simultaneously, a machine learning model predicts key quality metrics, such as free lime content, from the process data.

- Intelligent Action: The system provides a real-time prediction of clinker quality, long before physical lab results are available.

- Outcome: Operators can make immediate, small adjustments to the process to keep quality consistently on-spec. This reduces the production of off-spec material and eliminates wasteful “quality giveaway.”

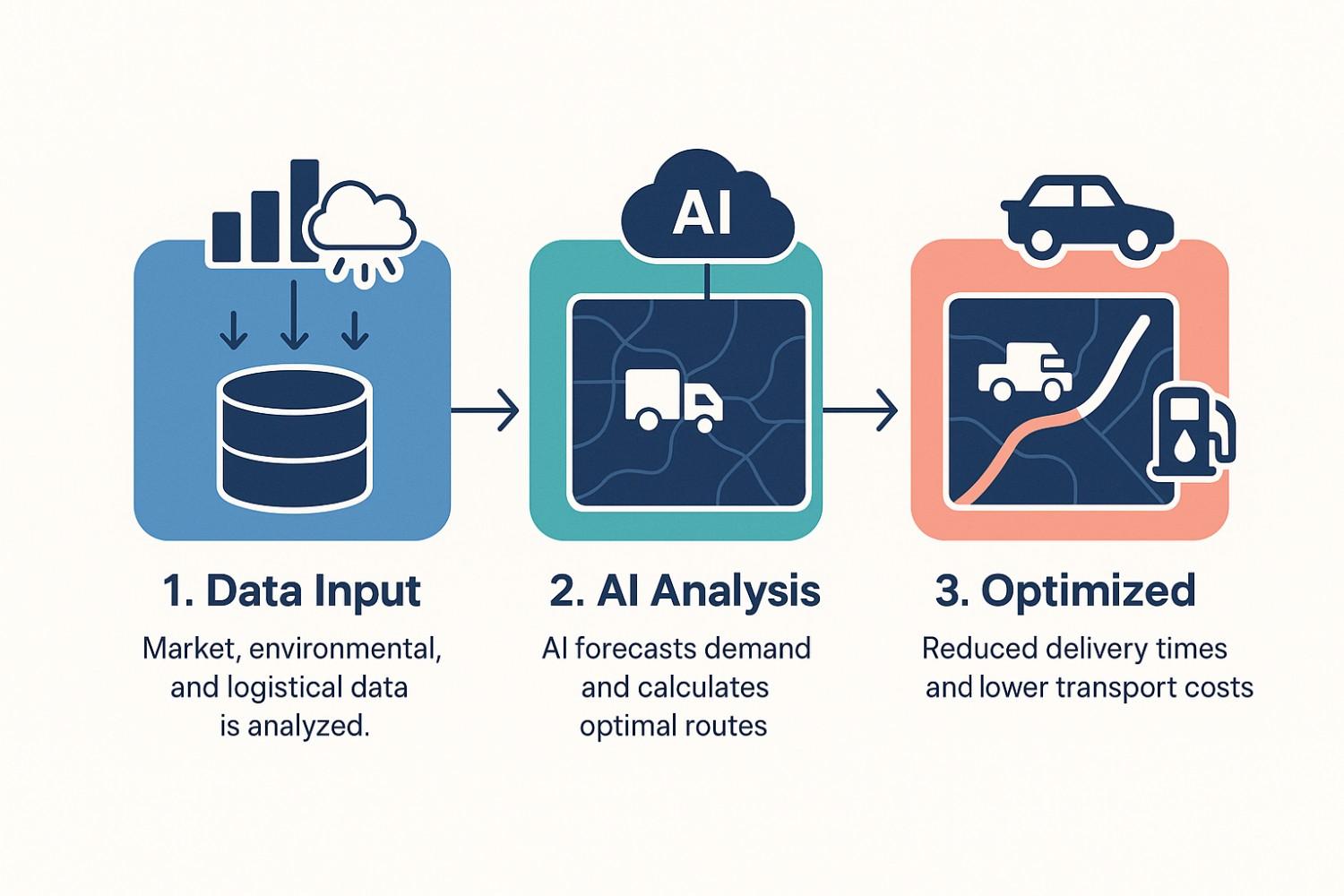

Solution 4: Supply Chain and Logistics Optimization

This solution addresses inefficiencies in inventory and delivery, from the plant to the customer.

- Data Input: It analyzes a wide range of data, including historical sales figures, market trends, weather patterns, real-time traffic, and customer delivery windows.

- AI Analysis: AI-powered forecasting models create highly accurate demand predictions. A separate logistics optimization model continuously calculates the most efficient dispatch and routing plans.

- Intelligent Action: The system provides optimized production schedules based on demand forecasts and generates dynamic, fuel-efficient routes for the delivery fleet.

- Outcome: This leads to better inventory management (reducing stockouts and overproduction), lower transportation costs, and improved on-time delivery rates, boosting customer satisfaction.

Output & Interaction: Empowering Operators and Management

This intelligence is delivered in a way that empowers, rather than replaces, human expertise. Insights are presented on intuitive dashboards. These can often integrate directly into the control room’s existing Human Machine Interface (HMI) (a user interface or dashboard that connects a person to a machine or system).

The system can operate in two modes:

- Open-Loop: The AI provides optimized setpoint recommendations for operators to review and approve before implementation.

- Closed-Loop: With operator oversight, the system can automatically implement the optimized setpoints, making small, frequent adjustments to maintain peak performance.

This approach transforms the operator’s role from a reactive troubleshooter to a strategic overseer, managing the process by exception and validating the AI’s high-level guidance. The powerful applications of AI in cement industry are designed to augment human skill.

4. Key Enabling Technologies: The AI Toolkit for Cement Manufacturing

Several core technologies enable this intelligent optimization. The smart application of these tools is fundamental to successful AI in cement manufacturing.

- Model Predictive Control (MPC): (A sophisticated control method that uses a dynamic mathematical model of a process to predict its future behavior. It is ideal for optimizing complex, multi-variable systems like cement kilns.) (In these systems, a change in one variable, like fuel rate, has delayed and interactive effects on others, like temperature and clinker quality.) The use of MPC is a cornerstone of AI in cement kilns (https://literature.rockwellautomation.com/idc/groups/literature/documents/wp/rswpcm-wp001_-en-p.pdf).

- Machine Learning for Predictive Maintenance: (This involves training algorithms on historical sensor data to recognize the “normal” operating signature of a machine. By using Time-Series Analysis, the system can detect subtle deviations from this norm that are precursors to failure.) (Algorithms like Isolation Forest are particularly effective at identifying these rare anomalous events in vast datasets.).

- Computer Vision: (An AI field that trains machines to interpret and understand the visual world. In a cement plant, this can involve analyzing real-time video of the kiln flame to assess combustion efficiency.) (It can also involve examining images of clinker on a conveyor to predict its chemical composition and quality in real-time, long before lab results are available.).

- Reinforcement Learning (RL): (An advanced AI technique where a software ‘agent’ learns to make optimal decisions by trial and error in a virtual environment that mimics the plant. Over millions of simulated runs, it discovers control policies for systems like the kiln that can outperform even those designed by human experts).

Ready to see how these technologies can be applied to your specific challenges?

Explore Our AI Development Services5. Potential Impact & Benefits for Cement Manufacturing

The implementation of AI in cement manufacturing delivers compelling, quantifiable returns by directly addressing the primary cost and production drivers. The benefits are not just additive; they compound, as improvements in one area create a positive feedback loop that enhances others.

- Reduced Fuel Consumption & CO2 Emissions: By continuously optimizing the kiln and eliminating conservative safety buffers, AI systems can deliver substantial savings. Plants have reported up to a 10% reduction in energy costs and fuel consumption, with some seeing energy efficiency improvement rates of up to 10 percent, directly lowering a plant’s largest operational expense and its carbon footprint.

- Increased Asset Uptime and Reliability: Predictive maintenance fundamentally changes the maintenance paradigm. By shifting from reactive repairs to proactive, data-driven interventions, plants can reduce unplanned downtime by up to 50%, preventing catastrophic failures that cost hundreds of thousands of dollars per hour.

- Improved and Consistent Clinker Quality: Real-time quality prediction and control can reduce quality variance by 30%, minimizing the production of off-spec material and eliminating wasteful “quality giveaway”. This ensures every ton of cement produced is profitable.

- Enhanced Throughput and Productivity: A more stable, reliable, and optimized process allows plants to safely push production closer to their true operational limits. This often results in a 3–8% increase in productivity and can be even higher in some cases.

- Streamlined Logistics and Lower Transport Costs: For the final step in the value chain, AI-driven route and network optimization can significantly reduce travel times and fuel usage for the delivery fleet. This improves on-time-in-full (OTIF) rates (https://throughput.world/blog/case-study-ai-logistics-optimization-cement-manufacturer/) and boosts customer satisfaction. The benefits of AI in cement manufacturing extend across the entire operation.

These benefits are not just theoretical. See the results we’ve delivered for clients.

View Our Case Studies6. Important Considerations for Implementation

Successfully deploying AI in cement manufacturing is not just a technology project; it is a socio-technical systems integration challenge. It requires careful planning and expertise. The following factors are critical for success.

- Data Infrastructure & Quality: AI models are only as good as the data they are trained on. A successful project requires a strategy to access clean, high-quality, and sufficient historical data. This often involves breaking down “data silos” where information is trapped in isolated systems across the plant.

- Integration with Legacy Systems: The new AI system must communicate seamlessly with the plant’s existing “brain”—the DCS and SCADA systems. This is a significant technical challenge that requires deep expertise in both modern AI platforms and legacy industrial control protocols. This is a key part of automation in cement manufacturing.

- Workforce Upskilling & Change Management: Operators and engineers must be trained to understand, trust, and collaborate with the AI’s recommendations. This involves clear communication and demonstrating how AI augments their expertise rather than replacing it. Effective change management is crucial for adoption.

- Scalability: From Pilot to Plant-Wide Rollout: The most effective approach is to begin with a high-ROI pilot project, such as optimizing a single kiln or monitoring a few critical grinding mills. This proves the value of AI in cement manufacturing quickly and provides a foundation for a clear strategy to scale the solution across the entire plant or enterprise.

- Model Maintenance and Governance: AI models can “drift” over time as operating conditions, equipment wears, or raw material characteristics change. A robust plan for continuous monitoring, retraining, and governance of the models is essential to ensure long-term performance and sustained ROI.

- Cybersecurity: Integrating information technology (IT) systems, like cloud-based AI platforms, with operational technology (OT) systems, like the plant’s DCS, introduces new potential security vulnerabilities. These must be proactively managed with robust cybersecurity protocols from the outset.

7. Tailoring AI for Your Unique Needs with Softlabs Group

The concepts discussed in this explainer provide a blueprint for the transformative potential of AI in cement manufacturing. However, realizing this potential requires moving from a blueprint to a bespoke architectural plan.

Every cement plant is unique, with different equipment, raw material geology, control systems, and operational constraints. An off-the-shelf AI product cannot effectively account for this critical nuance.

Achieving the full benefits of AI in cement manufacturing requires a partner that specializes in the deep analysis of these unique requirements. Softlabs Group works with clients to understand their specific challenges and operational environment. We then design and build truly custom AI solutions that are effective, scalable, and deliver a high return on investment. The future of efficient and sustainable cement production lies in this tailored application of artificial intelligence.

Let’s build a tailored AI solution that drives real value for your operations.

Discuss Your Custom AI Project