Executive Summary: The Imperative for Intelligent Leak Detection

High-stakes industries like oil, gas, and chemical manufacturing operate under constant pressure. In these environments, an undetected gas leak represents a severe operational, financial, and safety risk. Traditional detection methods, while foundational, often prove inadequate in complex, real-world conditions. This creates a dangerous gap between a leak’s occurrence and its discovery.

An AI gas leak detection system closes this gap. It represents a transformative shift from reactive checks to proactive, continuous surveillance. The journey to this advanced state doesn’t require a massive upfront investment. Instead, it begins with targeted pilot programs that prove value quickly. By starting small and scaling intelligently, an AI-Powered Gas Leak Detection approach becomes a practical and essential upgrade for resilient operations.

1. The Challenge: The High Cost of Outdated Gas Detection

Context: The High-Stakes Environment of Oil, Gas, and Chemical Facilities

The entire oil and gas value chain presents unique and significant risks. From upstream exploration to downstream refineries, the potential for hazardous gas leaks is a daily operational reality. Facilities handle volatile substances like Methane (CH₄) and toxic gases like Hydrogen Sulfide (H₂S). An undetected leak can have immediate and devastating consequences.

Therefore, robust safety and monitoring systems are not just a regulatory requirement. They are a fundamental pillar of responsible and sustainable operation in this sector.

Key Pain Points Addressed by AI

- Financial Losses: Leaks result in the direct loss of valuable product. They also trigger costly operational shutdowns, with a single work stoppage estimated to cost nearly $30,000. Subsequent emergency repairs and potential equipment replacement further escalate these expenses.

- Safety Hazards: The risk to human life is paramount. Toxic gases like H₂S are silent killers, while flammable gases like methane can cause catastrophic fires and explosions. These incidents endanger not only facility personnel but also surrounding communities.

- Environmental Damage & Regulatory Fines: Methane is a potent greenhouse gas, with a global warming potential approximately 84 times that of CO2 over a 20-year period. Uncontrolled emissions contribute significantly to climate change and can result in severe fines for violating stringent environmental regulations.

- Operational Inefficiency: Traditional leak detection often relies on manual inspections. These processes are labor-intensive, time-consuming, and difficult to conduct consistently, especially in large facilities or hard-to-reach areas. This manual dependency creates inconsistencies and increases operational overhead.

Limitations of Traditional Approaches

- Delayed Response: Traditional point detectors are passive. They require a gas cloud to accumulate and physically travel to the sensor’s location to trigger an alarm. In open, ventilated areas, wind can easily disperse the gas, meaning a dangerous leak may never be detected.

- Environmental Vulnerability: The performance of many conventional sensors degrades significantly in harsh conditions. High humidity, dust, and extreme temperatures can all compromise sensor accuracy. Furthermore, acoustic “sniffer” methods are rendered ineffective by wind.

- High False Alarm Rates & Sensor Poisoning: Conventional sensors are susceptible to “poisoning” from other chemicals in the environment. This can cause them to fail silently, creating a false sense of security, or trigger false alarms from benign sources, leading to unnecessary and expensive production shutdowns.

- Lack of Localization: When a traditional alarm does sound, it often only indicates that gas is present in a general area. It fails to pinpoint the exact source of the leak. This ambiguity delays repairs and forces maintenance crews to search for the source in a potentially hazardous environment.

- Labor-Intensive and Risky: Manual inspections with handheld devices are inefficient. They depend on skilled professionals walking the facility, a process prone to human error, inconsistency, and rushing. Most importantly, this approach requires personnel to enter potentially dangerous areas to find leaks.

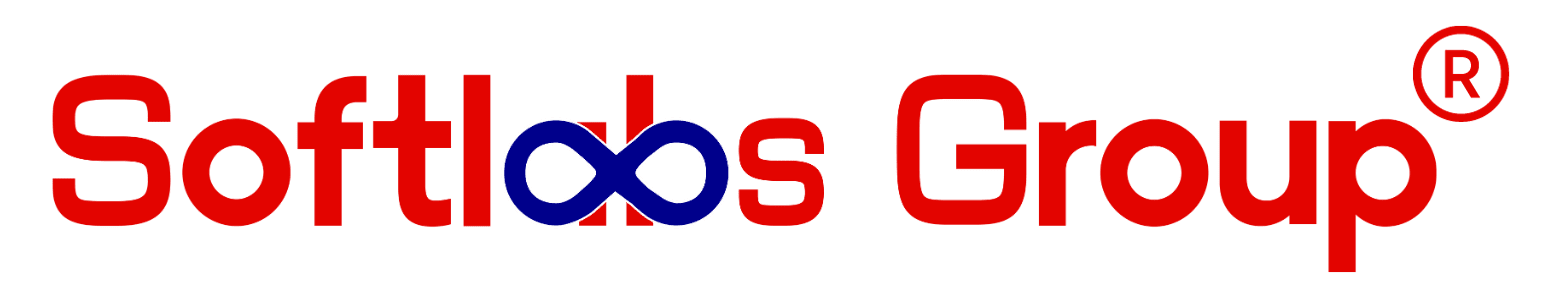

| Feature | Traditional Method | AI-Powered Method |

|---|---|---|

| Detection Speed | Slow; relies on gas accumulation at sensor. | Instantaneous; detects leaks at the source. |

| Accuracy & False Alarms | Prone to false alarms and silent failures. | High accuracy; AI distinguishes real leaks from noise. |

| Environmental Resilience | Performance degraded by wind, dust, and humidity. | Robust; combines sensors immune to wind and dilution. |

| Leak Localization | Provides general area alerts, no precise location. | Pinpoints the exact source of the leak visually and acoustically. |

| Operational Requirement | Labor-intensive manual inspections. | Fully automated, 24/7 autonomous monitoring. |

| Data & Insights | Limited to binary alarm data (leak/no leak). | Generates rich data for predictive maintenance and compliance. |

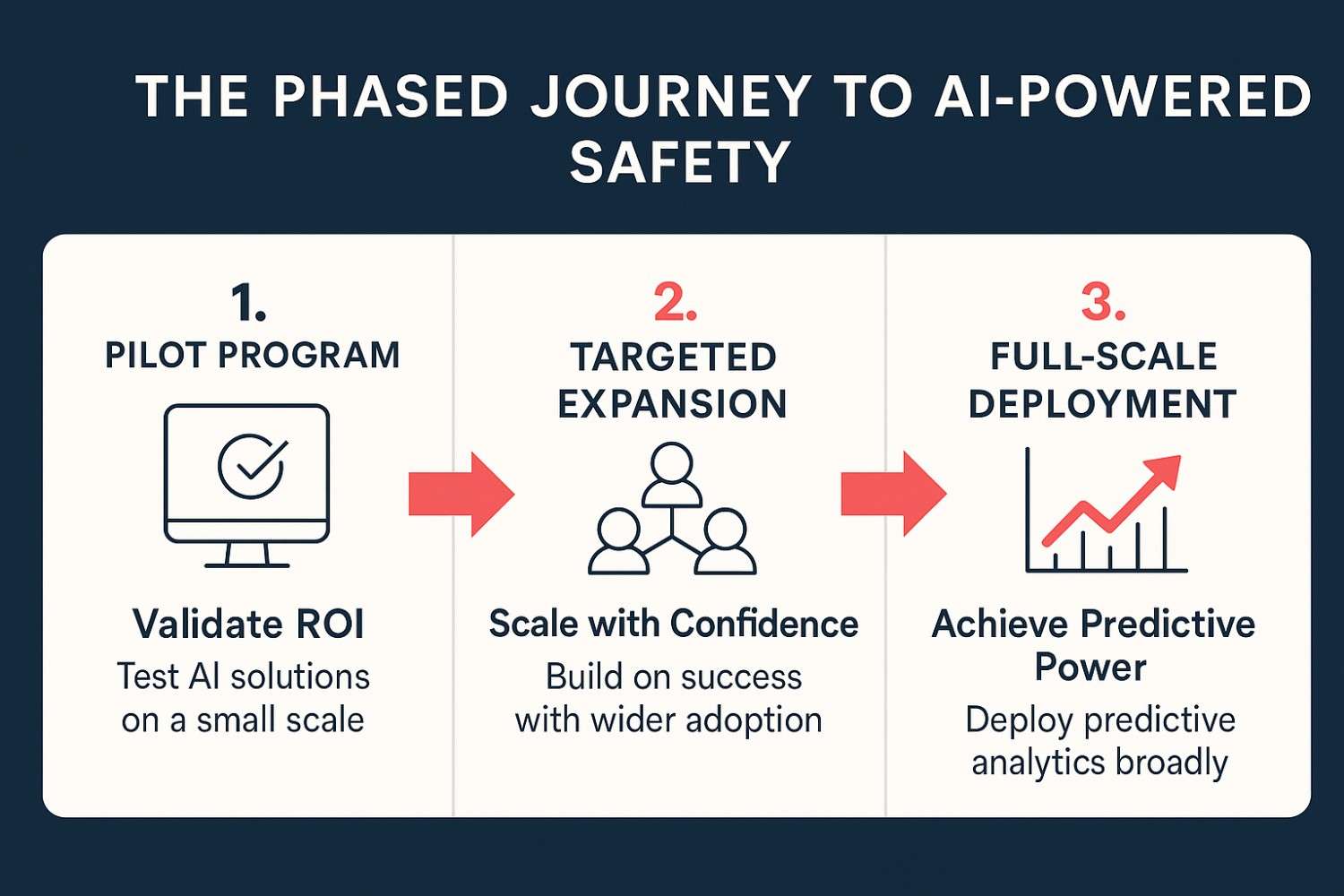

2. The AI Solution Concept: A Phased Journey to Intelligent Safety

Vision: From a Low-Risk Pilot to a Full-Scale Solution

The vision for a modern AI gas leak detection system begins not with a massive, facility-wide overhaul, but with a targeted, scalable pilot program. The journey starts by proving the technology’s value in a single, high-impact area. Success in this initial phase builds the confidence and provides the data-backed ROI needed to justify a strategic, enterprise-wide rollout. This approach de-risks the investment and ensures the final solution is perfectly aligned with real-world operational needs.

Objectives of a Phased Implementation

Phase 1: Pilot Program Objectives

- To validate the accuracy and reliability of an AI gas leak detector in a specific, high-risk operational area.

- To establish a clear, measurable ROI by quantifying reductions in response time and potential product loss.

- To demonstrate seamless integration with existing SCADA systems on a small scale.

- To build operator trust and confidence in the new technology with minimal disruption.

Phase 2 & 3: Full-Scale System Objectives

- To achieve near-instantaneous, 24/7 automated detection of gas leaks across all critical facility areas.

- To provide precise, visually confirmed location data for every detected leak, enabling rapid repair.

- To minimize false positives by using advanced sensor fusion and AI to distinguish real threats from benign events.

- To generate a rich, auditable log of data that supports predictive maintenance strategies and long-term asset integrity programs.

Ready to see how a custom AI solution can transform your operations? Let’s explore the possibilities together.

Explore Our AI Development Services3. How It Works: A Practical, Phased Implementation

An effective AI gas leak detection system is not deployed all at once. It is built through a practical, phased approach that prioritizes proving value and minimizing initial investment. This journey allows an organization to see tangible results before committing to a broader rollout.

Phase 1: The Low-Cost, High-Impact Pilot Program

The first step is a focused Proof-of-Value (PoV) pilot. This is the “working demo” that provides concrete evidence of the technology’s effectiveness.

- Targeted Deployment: Instead of monitoring the entire facility, the pilot focuses on a single, high-risk area, such as a specific compressor station or a known trouble spot on a pipeline. This controlled scope makes the project manageable and cost-effective.

- Leveraging Existing Infrastructure: To minimize upfront costs, the pilot is designed to layer on top of existing systems. It can utilize data from the client’s current Supervisory Control and Data Acquisition (SCADA) system, such as pressure and flow readings, to provide immediate context without requiring a complete hardware overhaul.

- Cost-Effective Sensing: Where new sensors are needed, the pilot uses a limited and targeted deployment. For instance, a single, highly effective ultrasonic acoustic detector can be installed to monitor the chosen area. This provides a powerful new data stream without the cost of a full sensor network.

- The Goal: The objective is to demonstrate core value quickly. This pilot proves its ability to detect leaks faster and more accurately than traditional methods, providing a clear, data-backed ROI for that specific use case. This aligns with best practices to “start small, scale fast” when integrating AI.

Phase 2: Scaling with Confidence

Once the pilot program has proven its value, the business case for expansion builds itself.

- Data-Driven Rollout: Using insights from the pilot, the solution is expanded to other high-priority areas. The client has full control, scaling the investment only after the initial phase has met or exceeded expectations.

- Layering Advanced Capabilities: As the system expands, more advanced technologies can be layered on. This could involve adding Optical Gas Imaging (OGI) Cameras (Specialized infrared cameras that can visualize invisible gas plumes) to provide visual confirmation of leaks, creating a powerful multi-modal detection system.

Phase 3: Full-Scale Predictive Monitoring

This is the mature stage of the solution, achieved after confidence has been built and value demonstrated across multiple areas.

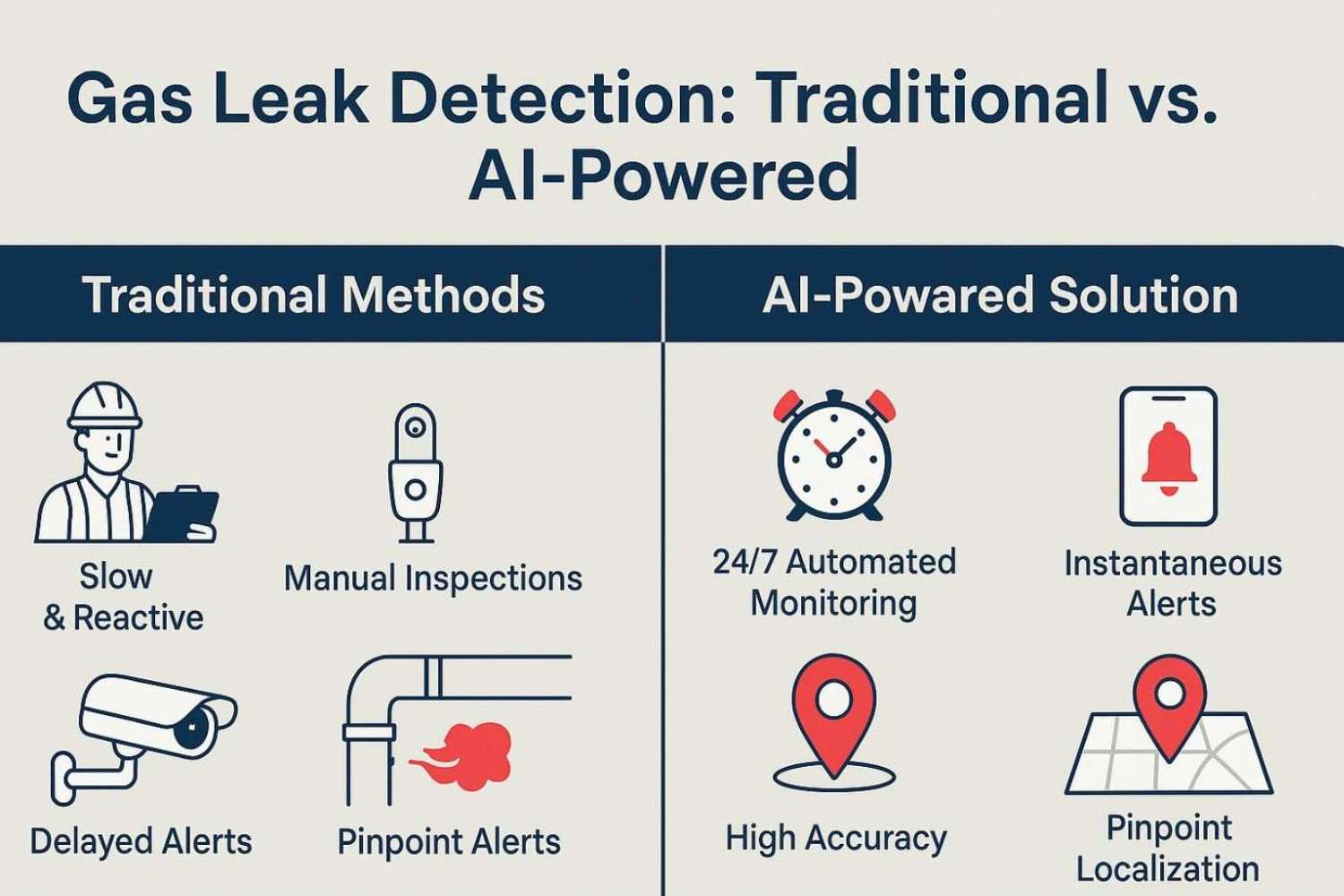

- Sensor Fusion and AI Analysis: The fully deployed system uses a network of sensors (OGI, acoustic, thermal) and feeds their data into a central AI platform. The AI performs sensor fusion, correlating data from multiple sources to validate leaks with extremely high confidence and eliminate false alarms.

- Proactive Intelligence: With a rich dataset from across the facility, the AI shifts from simple detection to true predictive maintenance. It identifies subtle patterns that precede equipment failure, allowing for proactive repairs before a leak occurs. This is the ultimate goal of a mature AI gas leak detection strategy.

4. Key Enabling Technologies: From Pilot to Full Scale

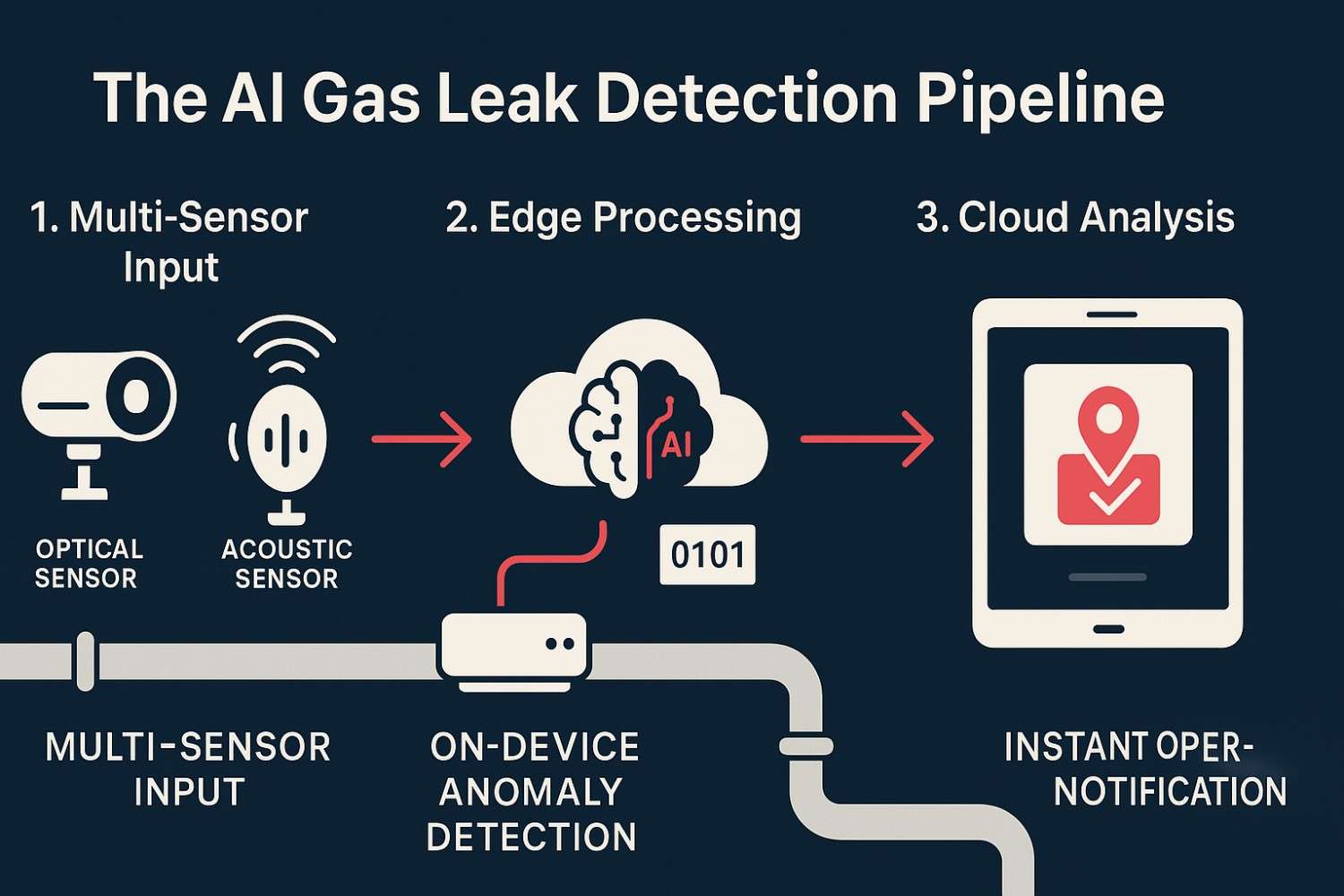

The technology stack for an AI gas leak detection system evolves with each phase of implementation, allowing for a gradual and justified investment.

Core Pilot Technologies (Phase 1)

- Ultrasonic Acoustic Detectors: The “ears” of the system. These specialized sensors listen for the distinct, high-frequency sound of pressurized gas leaks. They are cost-effective, immune to wind, and provide instantaneous detection at the source.

- Existing SCADA Data: The pilot leverages data from existing pressure and flow sensors to provide crucial operational context without requiring new hardware investment.

- Edge Computing: Lightweight AI models run on small, on-site devices. This allows for real-time analysis and alerting without needing to stream massive amounts of data to the cloud, keeping latency and bandwidth costs low.

Full-Scale System Technologies (Phase 2 & 3)

- Optical Gas Imaging (OGI) Cameras: The “eyes” of the full system. These advanced infrared cameras visualize invisible gas plumes, providing visual confirmation and precise location of leaks.

- Convolutional Neural Networks (CNNs): The primary AI model for visual analysis. CNNs are trained to automatically identify the unique visual signature of a gas plume and differentiate it from false alarms like steam or heat haze with remarkable accuracy.

- Cloud Platform & Advanced Analytics: The central “brain” of the enterprise solution. The cloud platform aggregates data from all sensors, performs advanced multi-modal fusion analytics, and hosts the user dashboards for facility-wide monitoring.

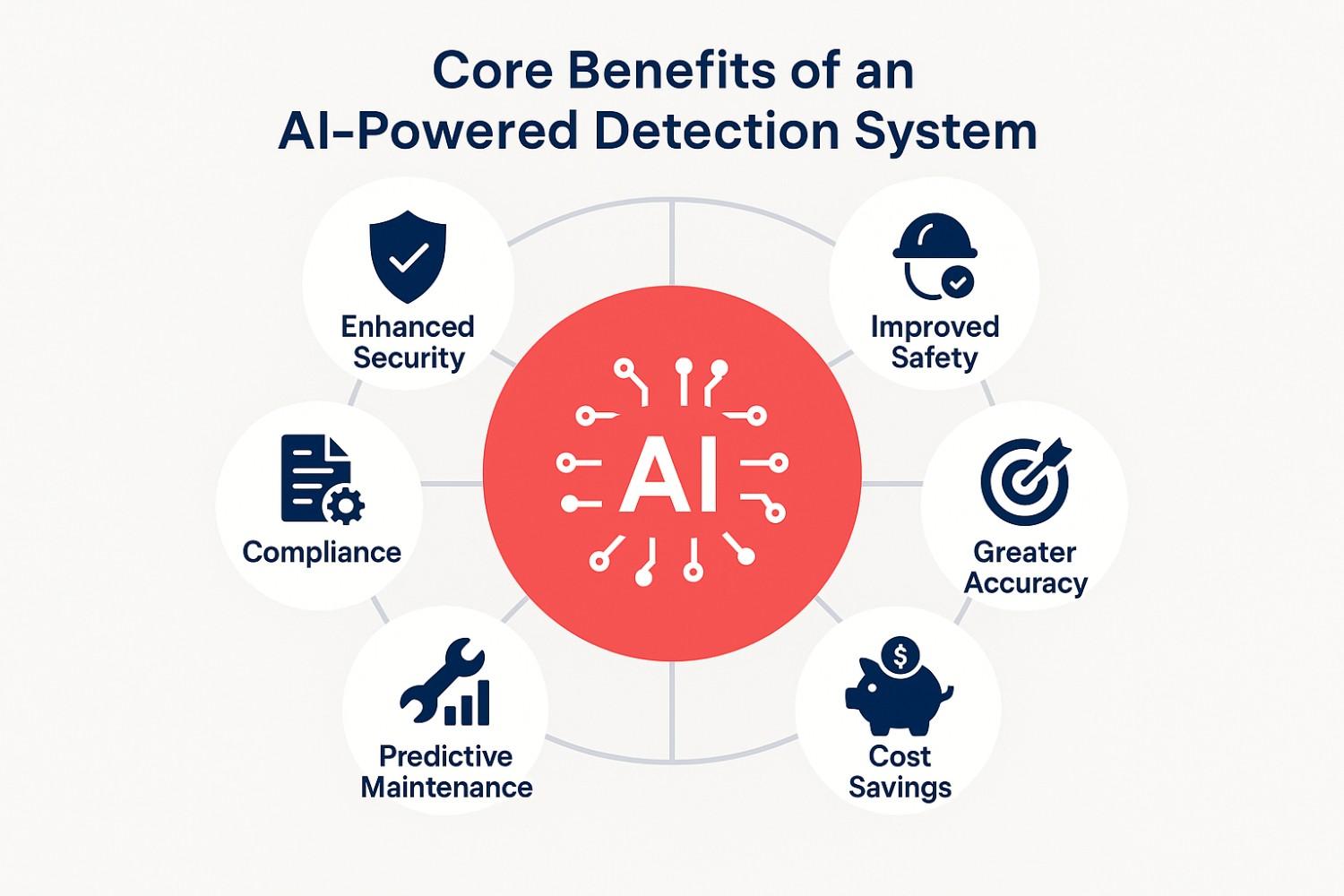

5. Potential Impact & Benefits for the Oil & Gas Industry

By starting with a focused pilot and scaling intelligently, facilities can progressively unlock the following strategic benefits. This journey transforms how facilities manage safety, efficiency, and compliance, turning the AI gas leak detection system into a powerful engine for business intelligence.

- Enhanced Safety and Risk Mitigation: The system provides the earliest possible warning of hazardous leaks. This immediate detection allows for rapid intervention, drastically reducing the risk of fires, explosions, and toxic exposure, thereby protecting both personnel and assets.

- Significant Operational Cost Reduction: By preventing product loss from leaks and avoiding costly unplanned downtime, the system delivers a strong return on investment. A case study of an AI-powered integrity management system demonstrated a 22% decrease in annual operational costs by proactively preventing pipeline leaks.

- Improved Detection Speed and Accuracy: AI dramatically shortens the timeline for discovery, with documented cases of reducing anomaly detection time from several days to under five minutes. AI models can achieve over 95% detection accuracy, which is critical for minimizing the false alarms that can lead to expensive and disruptive shutdowns.

- Optimized Maintenance and Asset Lifecycle: The system generates a rich historical dataset of all leak events. This data enables a strategic shift from inefficient, time-based maintenance schedules to highly efficient, condition-based predictive maintenance. By identifying which components are most at-risk, companies can optimize repair schedules and have been shown to improve asset lifecycle performance by up to 18%.

- Verifiable Regulatory and ESG Compliance: The system automatically generates detailed, auditable reports for every detected event. This provides concrete, quantifiable data to demonstrate compliance with regulatory bodies and supports corporate Environmental, Social, and Governance (ESG) goals.

- Increased Operational Uptime: By predicting and preventing equipment failures that cause leaks, AI contributes directly to production continuity. One major oil company projected an annual economic impact of approximately $800 million from the full deployment of a predictive analytics solution.

The impact of AI-driven safety and efficiency is clear. Explore real-world examples of how we’ve helped businesses transform their operations.

View Our Case Studies6. Important Considerations for a Phased Implementation

Deploying an effective AI gas leak detection system requires careful planning and expertise. Viewing these considerations through the lens of a phased, pilot-first approach makes them manageable steps on the path to success.

- Data Quality for the Pilot: The success of the initial pilot depends on quality data. This involves ensuring the chosen sensors are well-calibrated and that the data from existing SCADA systems is clean and accessible. This focused effort is far more manageable than attempting to wrangle enterprise-wide data from day one.

- Strategic Sensor Placement: For the pilot, a thorough site analysis is needed to determine the optimal placement of the initial sensors. The goal is to achieve comprehensive coverage of the target high-risk area to guarantee a successful proof-of-value.

- Initial System Integration: Integrating the pilot system with existing platforms like SCADA is critical. This initial integration serves as a template for the broader rollout, proving that the technology can communicate effectively with core operational systems before a larger investment is made.

- Cybersecurity from the Start: Even a pilot program requires a robust security strategy. Measures like network segmentation, data encryption, and strict access controls must be implemented from the beginning to protect the operational technology (OT) network.

- Model Maintenance and Retraining: An industrial environment is not static. A plan for continuous model maintenance is essential. This involves regularly monitoring the pilot model’s performance and retraining it with new data to ensure it remains accurate as conditions evolve.

- Building Operator Trust: For the system to be effective, operators must trust its alerts. The pilot phase is the perfect opportunity to involve control room personnel in the tuning and validation process. Running simulations with the pilot system helps build confidence and ensures operators are ready to act on the alerts.

7. Tailoring AI for Your Unique Needs with Softlabs Group

We understand that committing to a large-scale AI project based on theory alone is not a viable business strategy. The fear of a heavy upfront investment for an unproven technology is a significant barrier to innovation. That is precisely why we champion a pragmatic, partnership-based approach that is designed to eliminate this risk.

Our process begins with a conversation, not a sales pitch. We focus on understanding your most pressing operational challenges and then design a targeted, low-cost AI prototype or pilot program to address them. This allows you to see a working solution in your own environment, solving a real problem, and delivering measurable results with minimal initial outlay. We believe in proving the value of an AI gas leak detection solution first.

This pilot-first methodology de-risks your investment and builds internal confidence. It ensures that by the time you are ready to scale, the solution has already demonstrated its worth and is perfectly tailored to the unique layout, equipment, and processes of your facility. With Softlabs Group, you are not just buying a product; you are partnering with a team of experts dedicated to building a bespoke AI framework that grows with your needs and is justified by tangible ROI every step of the way.

Every facility is unique. A one-size-fits-all approach won’t deliver the results you need. Let’s start a conversation about your specific challenges and goals.

Discuss Your Custom AI Project