Executive Summary: The Next Evolution in Factory Management

The AI Manufacturing Execution System (MES) stands as a cornerstone of modern production, a critical digital bridge connecting high-level enterprise planning with the tangible reality of the shop floor. For decades, these systems have excelled at monitoring, documenting, and controlling manufacturing processes. However, the evolution towards an

AI Manufacturing Execution System highlights a fundamental limitation in traditional platforms: they are inherently reactive. They meticulously record what has already happened but possess little to no foresight, creating an operational ceiling that manufacturers now find increasingly restrictive. This reactive posture is no longer sufficient in a market that demands unprecedented agility and efficiency.

The next leap forward is the AI Manufacturing Execution System (AI-MES). This represents not merely an upgrade but a fundamental paradigm shift. An AI Manufacturing Execution System transforms the traditional system of record into a proactive, intelligent engine that drives the entire factory ecosystem. By embedding artificial intelligence at its core, this advanced

It moves beyond simple data collection to unlock predictive and prescriptive insights. It enables powerful capabilities such as forecasting equipment failures before they happen, automating quality control with superhuman precision, and dynamically optimizing production schedules in real time. This evolution is at the heart of the next industrial revolution, a trend reflected in a global AI in manufacturing market projected to grow exponentially into a multi-billion dollar industry by 2030.

1. The Challenge & Need for an AI Manufacturing Execution System

To appreciate the transformative potential of an AI-driven approach, one must first understand the inherent limitations of the systems that manufacturers rely on today. While essential, traditional MES platforms create operational bottlenecks that cap efficiency and stifle agility.

Context: The Role of a Standard Manufacturing Execution System

A standard MES is the software layer that executes production operations. It takes high-level plans from Enterprise Resource Planning (ERP) systems—such as production orders and bills of materials—and translates them into actionable tasks on the factory floor. Its core functions, often defined by industry standards like ISA-95, include managing work orders, tracking raw materials and work-in-progress, enforcing quality checkpoints, and creating a detailed digital record of the entire production lifecycle. In essence, it provides visibility and control over what is happening on the shop floor at any given moment. This system provides the foundational data that an

AI Manufacturing Execution System leverages for higher-level intelligence.

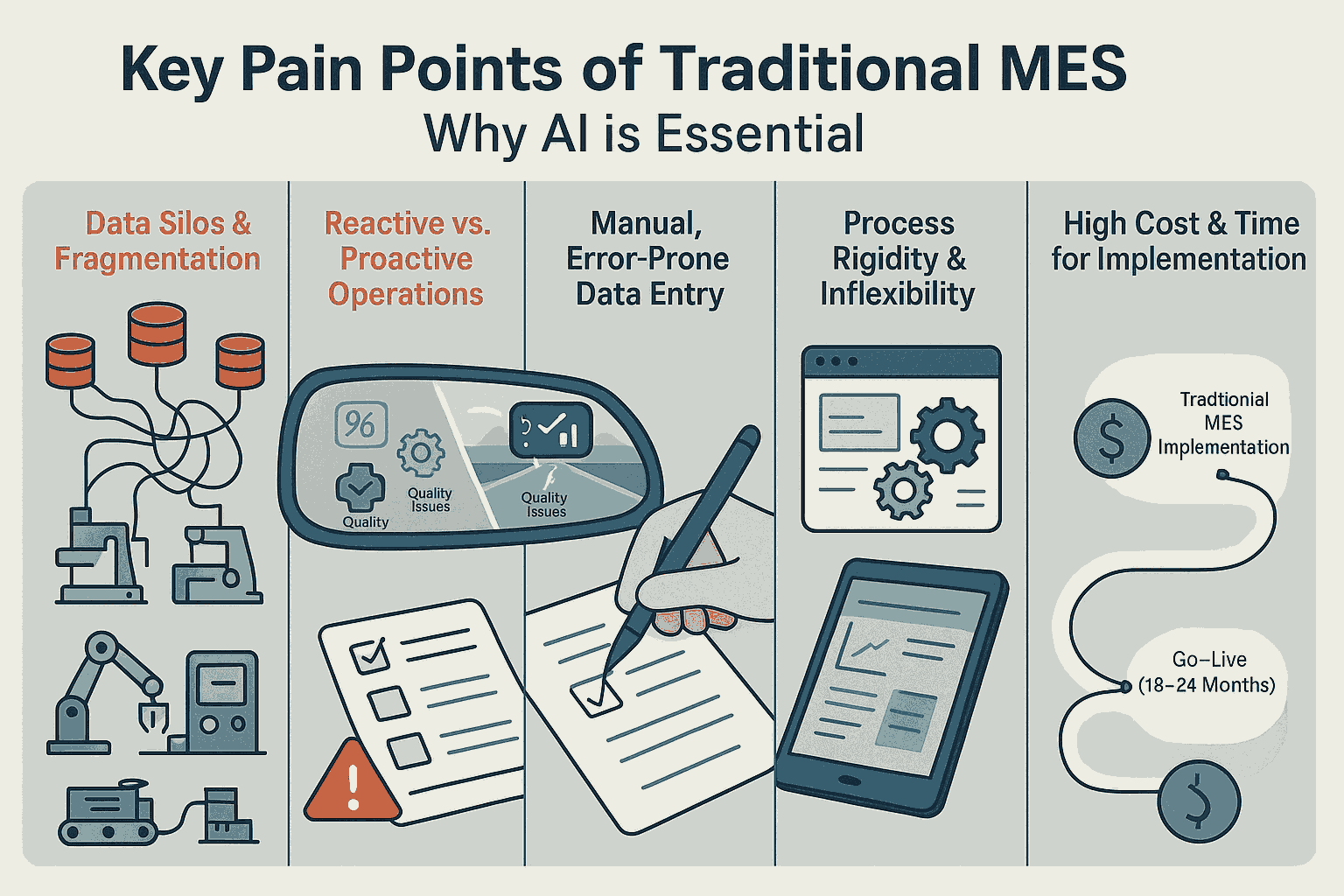

Key Pain Points Addressed by an AI Manufacturing Execution System

Despite their importance, legacy MES platforms present several critical pain points that prevent manufacturers from reaching their full potential. These systems create a data-rich but information-poor environment, a fundamental mismatch with the demands of the modern, agile market. This gap creates not just inefficiencies but a strategic vulnerability.

- Data Silos and Fragmentation: Factories often operate a mix of modern and legacy equipment from various vendors. Traditional MES struggles to integrate these disparate systems, leading to data silos where information is trapped within specific machines or departments. This results in an incomplete and often untrustworthy picture of the overall operation, making it impossible to perform holistic analysis.

- Reactive vs. Proactive Operations: The most significant limitation is that legacy systems are reactive. They are excellent at reporting on downtime, material scrap, and quality deviations after they have already occurred. This “rear-view mirror” approach offers little power to anticipate problems or prevent them from happening in the first place, leaving teams in a constant state of firefighting.

- Reliance on Manual, Error-Prone Data Entry: Many older MES platforms depend heavily on operators to manually input data, such as production counts or downtime reasons. This process is not only slow but also highly susceptible to human error. Furthermore, it relies on “tribal knowledge”—the invaluable experience of veteran workers—which is lost forever when they retire or leave the company.

- Process Rigidity and Inflexibility: Traditional MES architectures are often monolithic, making them difficult and expensive to customize. Instead of the software adapting to the manufacturer’s unique processes, the manufacturer is forced to adapt its processes to the software’s rigid structure. This inflexibility stifles innovation, slows down the introduction of new products, and hinders continuous improvement initiatives.

- High Cost and Time for Implementation: The cost and time required to implement, customize, or scale a traditional MES are notoriously high. A typical implementation can take 18-24 months and involve significant service costs. Because of this, deployments are often only justified for a company’s highest-volume or highest-margin product lines, leaving the rest of the factory to operate with less effective tools.

The following table contrasts the capabilities of a traditional MES with those of a modern AI Manufacturing Execution System.

| Capability | Traditional MES (The Reactive System of Record) | AI-Powered MES (The Proactive System of Intelligence) |

|---|---|---|

| Data Analysis | Collects and displays historical data. | Analyzes real-time and historical data to generate predictive and prescriptive insights. |

| Maintenance Strategy | Supports reactive or scheduled (preventive) maintenance. | Enables predictive maintenance, forecasting failures before they occur. |

| Quality Control | Documents quality checks and manages non-conformance after detection. | Uses computer vision and ML for real-time, automated defect detection and root cause analysis. |

| Production Scheduling | Manages static schedules based on pre-defined plans. | Performs dynamic scheduling, optimizing in real-time based on demand, machine availability, and supply chain data. |

| Operational Mode | Reports on past events (e.g., downtime, scrap rate). | Anticipates future events and recommends actions to prevent them. |

| Flexibility | Often rigid, with costly and slow customization. | Highly adaptive, with models that learn and adjust to new products and changing conditions. |

2. The AI Solution Concept: The AI Manufacturing Execution System

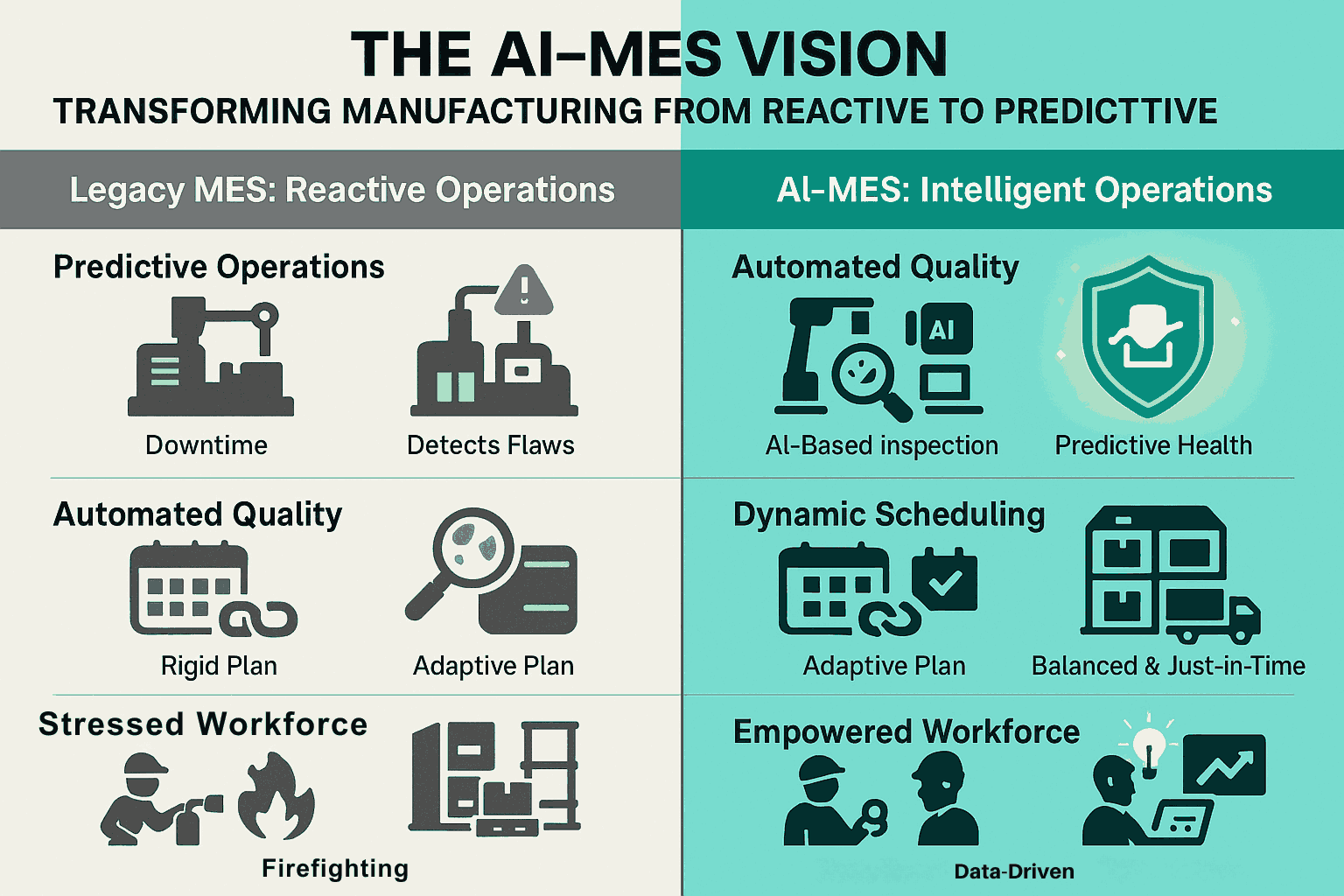

The AI Manufacturing Execution System is envisioned as a direct and comprehensive solution to the limitations of legacy systems. Its purpose is to transform the factory from a collection of siloed, reactive processes into a single, cohesive, and intelligent organism that can anticipate and adapt to change.

Vision & Objectives for an AI Manufacturing Execution System

The overarching vision is to create a self-optimizing production environment where data is transformed into foresight and intelligent action. This system moves beyond simple execution to achieve a state of operational predictability and control. The core objectives of such a system are designed to directly counteract the pain points of traditional MES and reduce the operational uncertainty that plagues modern manufacturing.

- Achieve Predictive Operations: The primary goal is to shift the entire operational paradigm from reactive to predictive. Instead of reporting on past failures, the system will use data to accurately forecast equipment breakdowns, identify potential quality deviations, and predict production bottlenecks well before they can disrupt the factory floor.

- Automate and Enhance Quality Assurance: The system will implement intelligent quality control that not only detects defects with superhuman accuracy in real time but also analyzes patterns to understand the root cause of those defects. This allows the system to move from merely catching errors to actively preventing them from recurring.

- Enable Dynamic and Optimized Scheduling: An AI Manufacturing Execution System will create fluid production schedules that adapt automatically and intelligently to real-world conditions. When a machine goes down, a priority order arrives, or a material shipment is delayed, the system will instantly re-optimize the schedule across the entire plant to maximize throughput and ensure on-time delivery commitments are met.

- Optimize Resource and Inventory Management: By leveraging AI-driven demand forecasting, the system will maintain optimal levels of both raw materials and finished goods. This eliminates the twin problems of costly overstocking and capital-intensive safety stock while preventing stockouts that can halt production or delay customer orders.

- Empower the Workforce: The system will transform the role of human workers. By providing operators and managers with clear, actionable, real-time insights and decision-support tools, it frees them from mundane data entry and firefighting. They evolve into strategic problem-solvers, empowered by AI to make better, faster decisions.

3. How an AI Manufacturing Execution System Works:

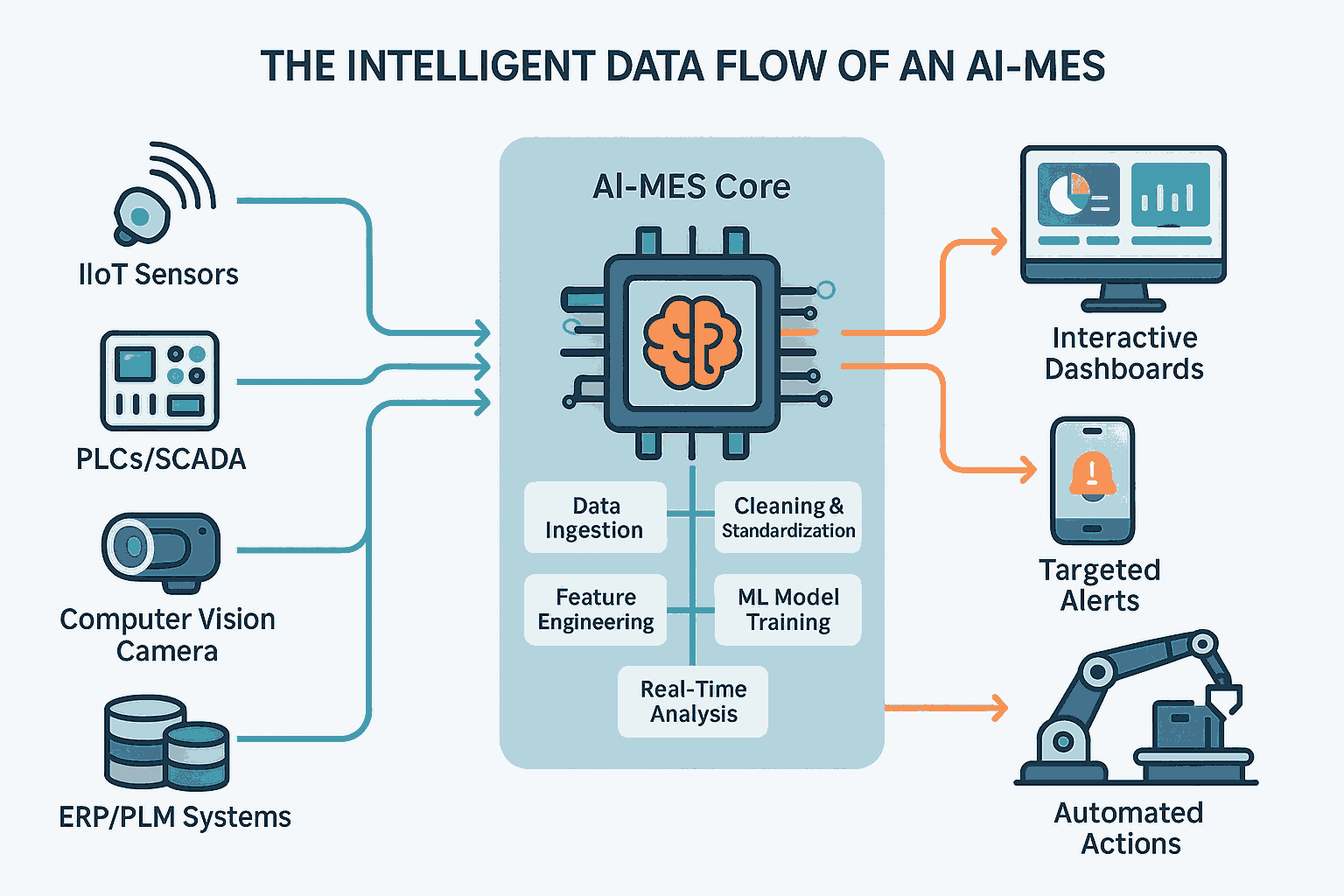

An AI Manufacturing Execution System functions by creating a continuous, intelligent loop of data acquisition, processing, and action. This process is designed to turn the cacophony of raw data from the factory floor into a clear, actionable signal that drives operational excellence.

Data Acquisition: Fueling the AI Manufacturing Execution System

The process begins with the comprehensive collection of data from every corner of the manufacturing environment, creating a digital nervous system that senses the state of the factory in real time. This is the essential sensory input that fuels the AI Manufacturing Execution System. Key data sources include:

- Industrial Internet of Things (IIoT) sensors embedded in machinery, which capture a constant stream of operational data such as temperature, vibration, pressure, acoustics, and energy consumption.

- Programmable Logic Controllers (PLCs) and SCADA systems, which provide data directly from the control systems governing machine operations.

- High-resolution computer vision cameras mounted on production lines to capture detailed visual data for quality inspection.

- Integrations with enterprise-level systems like ERP for work order details and production targets, and Product Lifecycle Management (PLM) for product specifications and design data.

The AI Processing Pipeline of an AI Manufacturing Execution System: From Raw Data to Actionable Intelligence

Once acquired, raw data is transformed into valuable intelligence through a sophisticated, multi-stage pipeline. This process effectively automates the diagnostic thinking of an expert engineer, but does so at a scale and speed that is humanly impossible.

1)First, the system ingests the raw data from all connected sources. This data flows into a centralized data platform, which may reside in the cloud, on-premise, or in a hybrid architecture, to create a single source of truth.

2) Next, the data undergoes rigorous preparation. This critical stage involves data cleaning, where the system handles missing values, corrects inconsistencies, and removes erroneous entries. It also performs data standardization, converting information from diverse legacy and modern systems into a unified format. The quality of AI-driven insights is entirely dependent on the quality of this foundational data.

3)Once the data is clean and structured, the system performs feature engineering. This is where domain expertise is codified, as the system selects the most relevant variables—or “features”—that will be used to train the AI models. For a predictive maintenance model, for instance, key features might include the rate of temperature change, specific vibration frequencies, and total operating hours since the last service.

4)The system then uses this curated data to train a suite of specialized Machine Learning (ML) models. Different models are built for different tasks. For example, Convolutional Neural Networks (CNNs) are trained on millions of images to master visual quality control, while regression and classification algorithms like Random Forests are trained on sensor data to predict equipment health.

5)After training and validation, these models are deployed into the live production environment. They begin analyzing the real-time data stream, constantly comparing it against the complex patterns of normal and abnormal behavior they learned during training. This allows them to identify subtle anomalies, predict impending failures, or classify defects with incredible accuracy.

6)Finally, the AI generates a clear, actionable output. This is the culmination of the entire pipeline: a specific insight or recommendation designed to drive an immediate, value-added action.

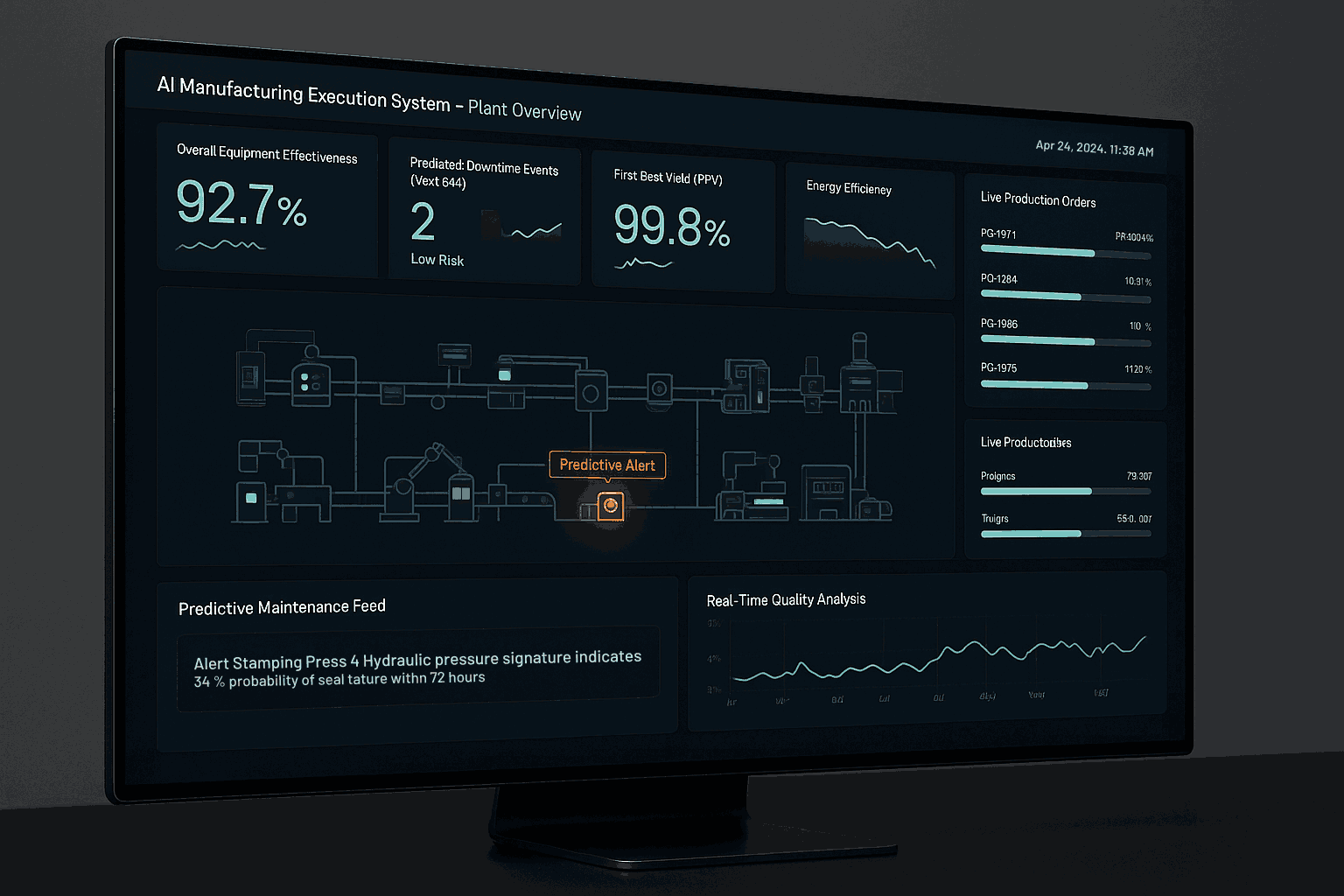

Output & Interaction: How an AI Manufacturing Execution System Delivers Insights

The intelligence generated by the AI Manufacturing Execution System is useless unless it is delivered to the right person, in the right context, at the right time. The system’s outputs are designed for immediate comprehension and action, not for complex interpretation. These outputs are presented through a variety of intuitive interfaces:

- Interactive Dashboards: Supervisors and plant managers access web-based dashboards that visualize real-time KPIs, overall equipment effectiveness (OEE), production goal attainment, and predicted bottlenecks.

- Targeted Alerts: An operator on the line might receive an alert on their tablet or a station’s Human-Machine Interface (HMI) screen. This alert will be specific and prescriptive, for example: “Alert: Bearing on CNC Mill #4 shows a vibration pattern consistent with failure in the next 72 hours. A work order has been created for the next scheduled maintenance window.”

- Automated System Triggers: The AI can directly trigger actions in other systems without human intervention. For instance, it can automatically generate a maintenance work order in the CMMS, halt a conveyor belt when a critical quality defect is detected, or adjust process parameters on a machine to prevent a predicted deviation.

4. The AI Manufacturing Execution System Tech Stack

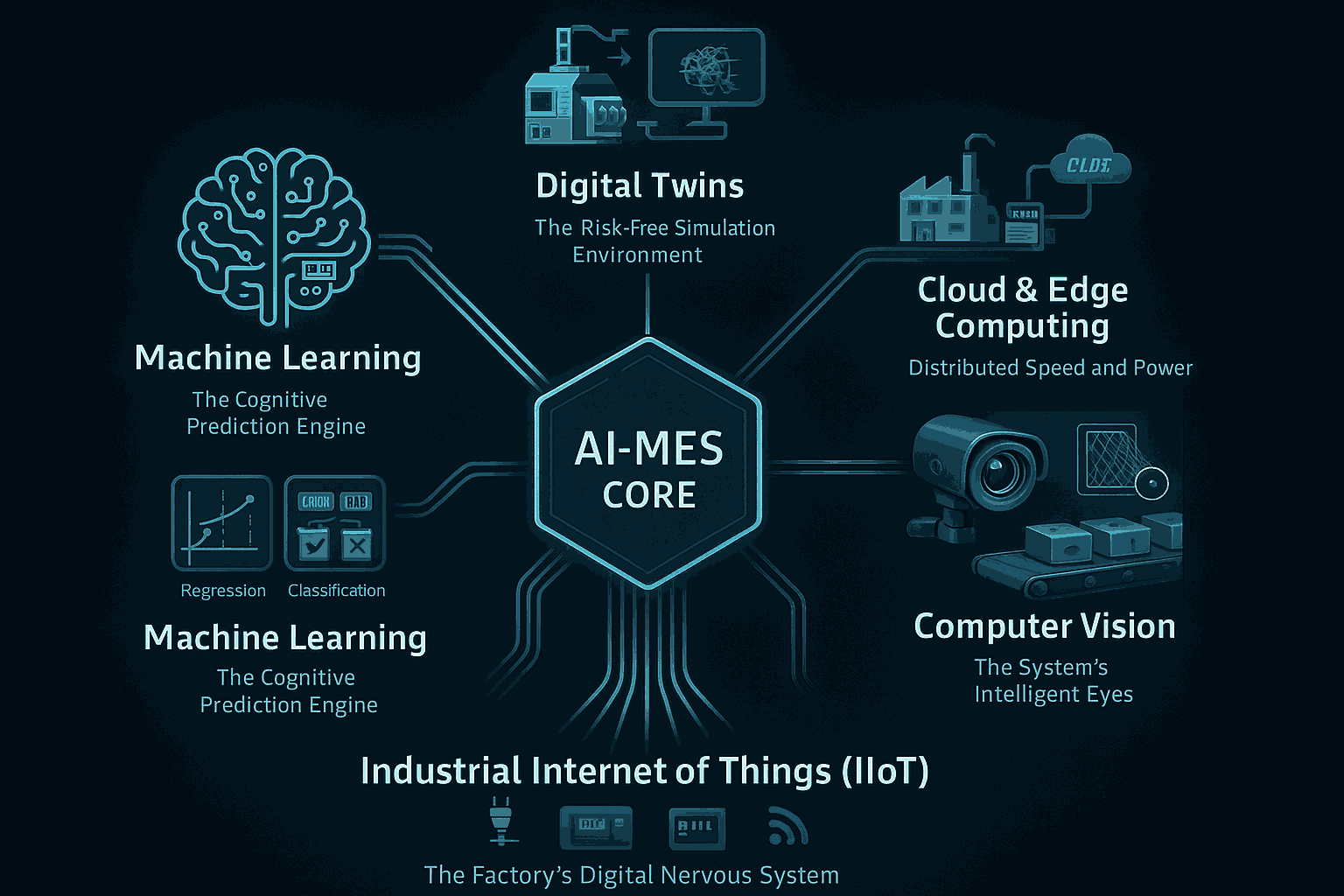

An AI Manufacturing Execution System is not a single piece of software but a complex ecosystem of interconnected technologies. Each component plays a distinct and vital role, and together they form a symbiotic stack where each layer enables the next, creating a system far more powerful than the sum of its parts. An AI Manufacturing Execution System relies on this stack to deliver its advanced capabilities.

- Industrial Internet of Things (IIoT) (A network of interconnected sensors, instruments, and other devices on the factory floor that collect and exchange real-time data). IIoT forms the foundational sensory layer of the AI-MES. It is the digital nervous system that captures the raw data from the physical world—the temperature, pressure, vibration, and visual information—that feeds every subsequent process. Without a robust IIoT infrastructure, the AI has no data to analyze.

- Machine Learning (ML) (A subset of AI where algorithms are trained on data to find patterns and make predictions without being explicitly programmed for the task). ML is the cognitive engine of the system. It encompasses a variety of algorithms tailored for specific manufacturing challenges. Regression Algorithms (ML models that predict a continuous value, like the remaining useful life of a component) are the core of predictive maintenance. Classification Algorithms (ML models that assign an item to a category, such as ‘defective’ or ‘non-defective’) drive automated quality control and root cause analysis. These include powerful models like Random Forests (An ensemble learning method that operates by constructing a multitude of decision trees at training time) and Support Vector Machines (SVM) (A supervised learning model that uses classification algorithms for two-group classification problems).

- Computer Vision (A field of AI that trains computers to interpret and understand the visual world from digital images or videos). This technology gives the MES “eyes,” enabling fully automated quality assurance. Using high-resolution cameras and sophisticated models, computer vision systems can identify microscopic defects, verify complex assemblies, and read labels with a speed and consistency that far surpasses human capabilities. The technology behind this is often Convolutional Neural Networks (CNNs) (A class of deep learning models, most commonly applied to analyzing visual imagery), which are trained to recognize the intricate visual patterns of both perfect products and a wide range of potential defects.

- Cloud & Edge Computing (A distributed computing paradigm that brings computation and data storage closer to the sources of data). This dual architecture provides both speed and power. Edge computing acts as the system’s local reflex, processing time-critical data directly on or near the factory floor. This is essential for decisions that require near-zero latency, like stopping a machine to prevent a safety incident. Cloud computing provides the massive, scalable storage and computational power needed for training complex AI models on vast datasets and performing long-term, plant-wide analysis.

- Digital Twins (A virtual model designed to accurately reflect a physical object, process, or system). The digital twin is the ultimate expression of the AI-MES’s intelligence. It is a dynamic, virtual replica of a machine, a production line, or even the entire factory, continuously updated with real-time data from IIoT sensors. This allows managers and engineers to simulate the impact of process changes, test optimization strategies, and visualize the progression of predicted failures in a completely risk-free virtual environment before implementing them in the real world.

Wondering how these technologies deliver real-world results?

5. Potential Impact & Benefits of an Manufacturing Execution System

The implementation of an AI Manufacturing Execution System translates directly into tangible, quantifiable business outcomes. By moving beyond reactive problem-solving to proactive optimization, this technology drives significant improvements in efficiency, quality, and cost savings, delivering a compelling return on investment. The benefits of an AI Manufacturing Execution System are not isolated; they create a compounding effect, where improvements in one area create a virtuous cycle that enhances others, widening the competitive gap between early adopters and laggards.

- Dramatically Reduced Downtime: AI-powered predictive maintenance is one of the most impactful applications. By forecasting equipment failures before they happen, manufacturers can shift from costly, disruptive emergency repairs to planned, efficient maintenance. Studies and real-world implementations show this can reduce unplanned downtime by up to 50% and cut overall maintenance costs by as much as 40%. Automotive giant BMW, for example, reported saving over 500 minutes of production disruption per year in a single plant by using AI to predict maintenance needs.

- Increased Productivity and Throughput: With machines running more reliably and production schedules dynamically optimized to eliminate bottlenecks, overall factory output increases significantly. Industry analysts project that AI will boost manufacturing productivity by up to 40% by 2035. Real-world case studies have documented throughput increases ranging from 15% to 27%.

- Superior Quality Control and Reduced Waste: Automated quality inspection powered by computer vision is both faster and more accurate than manual methods. AI systems can achieve over 95% accuracy in defect detection, catching subtle flaws that the human eye would miss. This leads to a dramatic reduction in scrap, rework, and warranty claims. One case study showed a 68% drop in scrap rates and another noted a 42% reduction in quality deviations after implementing AI.

- Optimized Production Planning and On-Time Delivery: AI algorithms can generate and adapt complex production plans in minutes, a task that can take human planners hours or even days. This capability has been shown to reduce production planning time by over 80% and increase on-time delivery performance by up to 25%.

- Enhanced Worker Safety: An often-overlooked benefit is the improvement in workplace safety. By predicting and preventing catastrophic equipment failures, AI systems mitigate a significant source of industrial accidents. In the United States alone, machinery operation and maintenance lead to approximately 18,000 injuries and over 800 fatalities per year; predictive maintenance directly addresses this risk.

- Significant and Rapid Return on Investment (ROI): While implementing an AI-MES requires an initial investment, the financial returns are both substantial and rapid. A mid-sized automotive components manufacturer, for example, nommas ai achieved 37% reduction in defects and a 22% improvement in OEE. Other financial analyses show that the average payback period for such projects can be as short as 9-14 months.

Ready to unlock these benefits with a tailored solution?

6. Important Considerations for Implementing the System

Successfully implementing an AI Manufacturing Execution System is a complex business transformation, not a simple technology installation. It requires careful strategic planning and a clear-eyed understanding of the potential challenges. Approaching the implementation of an AI Manufacturing Execution System as a risk management discipline is crucial for success. This involves addressing data, integration, financial, and human capital risks with expert guidance.

- Data Governance and Quality: This is the absolute foundation for any successful AI initiative. AI models are governed by the principle of “garbage-in, garbage-out.” If trained on inaccurate, incomplete, or inconsistent data, they will produce flawed and untrustworthy results. Organizations must prioritize establishing robust data governance policies and investing in the tools and processes for data cleansing, standardization, and validation. This is the most significant obstacle for many, with reports indicating that up to 70% of manufacturers cite data problems as a primary barrier to AI adoption.

- Integration with Legacy Systems: Few factories are built from scratch; new AI solutions must coexist and communicate with a complex landscape of existing infrastructure, including legacy equipment and enterprise software. A successful implementation requires a clear strategy for integration, typically using modern Application Programming Interfaces (APIs) and middleware solutions to act as translators. This approach bridges the gap between old and new systems, preventing the creation of new data silos and ensuring a seamless flow of information.

- Scalability and Architecture: A common pitfall is creating a successful pilot project that cannot be scaled to the entire enterprise. The system’s technical architecture must be designed for scalability from day one. This generally means favoring modular, cloud-based, or hybrid approaches that can grow and adapt with the business, while avoiding monolithic, on-premise designs that are rigid and difficult to expand.

- AI Model Maintenance and Drift: AI models are not static assets. Their predictive accuracy can degrade over time as production conditions, materials, or processes change—a phenomenon known as model drift. A successful AI strategy must include a plan for the entire model lifecycle. This involves continuous monitoring of model performance, periodic retraining with new data to keep them accurate, and robust versioning to manage updates effectively.

- Managing ROI and Starting Small: The uncertainty surrounding the return on investment is a major hurdle for many organizations. The most effective way to mitigate this financial risk is to adopt a phased approach. Instead of attempting a massive, factory-wide overhaul at once, best practice is to begin with a small-scale pilot project that targets a single, well-defined, high-impact business problem. This approach allows the organization to achieve a quick win, validate the business case with tangible results, and build internal support and momentum for a broader, more ambitious deployment.

- Human Capital and Change Management: Technology alone does not guarantee success. Overcoming workforce resistance and bridging the internal skills gap are critical. A successful implementation requires a thoughtful change management strategy. This includes transparently communicating AI’s role as a “copilot” designed to augment human workers, not replace them. It also involves investing in training and upskilling programs to equip existing staff with the skills needed to work effectively in a data-driven environment and fostering a culture that embraces continuous improvement.

7. Tailoring Your Unique Needs with Softlabs Group

The powerful, integrated AI Manufacturing Execution System described in this report represents a conceptual blueprint for the future of production. However, it is crucial to recognize that every manufacturing environment is unique. Your factory has its own specific equipment, proprietary processes, distinct data challenges, and singular business goals. Off-the-shelf software can only go so far in such a complex landscape. Realizing the full potential of an AI Manufacturing Execution System and achieving the transformative ROI figures detailed here requires more than a generic product; it demands a truly bespoke solution engineered to meet your specific operational context.

Softlabs Group specializes in precisely this. Our expertise lies not just in developing sophisticated AI models, but in deeply understanding the nuances of our clients’ manufacturing operations. We work with you to architect and build custom AI solutions that are meticulously tailored to solve your most pressing challenges and align directly with your strategic objectives. This collaborative, custom-development approach ensures the final AI Manufacturing Execution System is not just a powerful piece of technology, but a strategic asset that delivers measurable, lasting value to your business.

Let’s talk about how a custom AI solution can work for you