Executive Summary: Proactively Preventing Vibration Injuries with Intelligent Wearables

Millions of workers in construction and manufacturing face a daily threat that can lead to permanent, life-altering injuries. This threat, Hand-Arm Vibration Syndrome (HAVS), is an irreversible disease caused by prolonged exposure to vibrating tools. Traditional monitoring methods rely on inaccurate estimates and manual paperwork, creating a dangerous gap between compliance and actual worker safety.

To close this gap, Softlabs Group has developed an intelligent ai powered hand arm vibration monitoring device. Our proven, ready-to-use system transforms safety from a reactive task into a proactive, data-driven strategy. By measuring a worker’s actual vibration exposure and monitoring physiological indicators, our technology offers a precise, automated way to protect workers, ensure compliance, and foster a safer work environment.

1. The Challenge: The Pervasive and Underestimated Risk of Hand-Arm Vibration

Context: A Crippling Condition in Construction and Industrial Settings

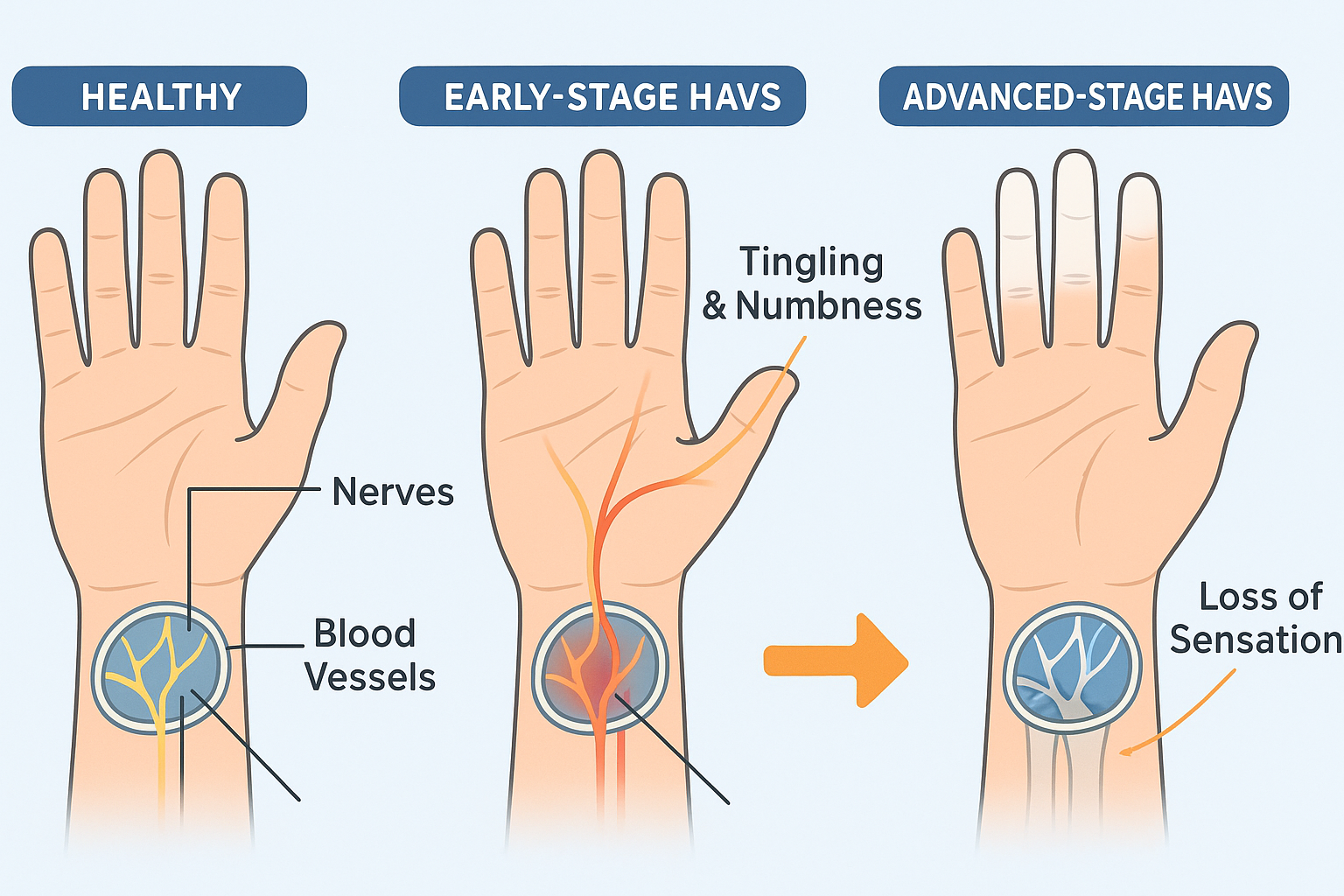

Hand-Arm Vibration Syndrome (HAVS) is a debilitating industrial disease from the prolonged use of vibrating hand-held machinery. The condition often begins with intermittent tingling and numbness in the fingers. As exposure continues, symptoms can advance to chronic pain, loss of grip strength, and episodes of “vibration white finger,” where fingers lose all sensation.

The damage to nerves, blood vessels, and joints is permanent. Once it occurs, it is irreversible, making prevention the only effective strategy.

The scale of this problem is staggering. In the United States alone, an estimated 1.45 million workers are exposed to hand-arm vibration. The prevalence of HAVS among these populations averages around 50%. This data highlights a widespread occupational health crisis that demands a more effective system for hand arm vibration monitoring.

Key Pain Points Addressed by an AI-Powered Hand Arm Vibration Monitoring Device

- Permanent, Life-Altering Injuries: Workers with HAVS face conditions that impact their quality of life. They often struggle with fine motor tasks like fastening buttons, experience sleep disturbances from pain, and are often forced to abandon their careers.

- Severe Compliance and Legal Risks: Employers have a legal duty to protect their workforce. Regulations like the UK’s Control of Vibration at Work Regulations 2005 mandate strict exposure limits. Failure to comply can lead to substantial fines and crippling legal liability.

- Inaccurate and Unreliable Risk Assessment: Traditional risk assessments rely on guesswork. Methods using manual logs and generic manufacturer vibration data often produce grossly inaccurate exposure calculations, leaving workers at risk.

- Lack of Real-Time Intervention: Without continuous monitoring, a supervisor has no visibility into a worker’s exposure levels during a shift. This reactive approach means there is no way to prevent an individual from exceeding safe limits.

- Hidden Impact of Worker Fatigue: Traditional safety protocols overlook the combined risk of vibration and physical fatigue. A tired worker may grip a tool with more force, yet this critical factor remains unmonitored. An ai powered hand arm vibration monitoring device can address this.

Limitations of Traditional Approaches

Traditional hand arm vibration monitoring equipment and methodologies are fundamentally flawed. They are built on unreliable assumptions that create a dangerous gap between the appearance of compliance and the reality of worker safety. A company’s paper trail may seem to meet legal requirements, but employees can still suffer overexposure because the underlying data is inaccurate.

The primary issue is the “estimation fallacy.” Using a manufacturer’s data sheet and a worker’s estimated “trigger time” is profoundly unreliable. Real-world vibration levels vary dramatically based on the tool’s age, the material being worked on, operator technique, and even ambient temperature.

Furthermore, workers’ recall of their total trigger time throughout a day is notoriously poor and often overestimated. This means that risk assessments are based on flawed inputs, leading to a false sense of security.

Additionally, these methods are reactive, not proactive. Data is reviewed after the fact, making it impossible to prevent an overexposure event as it happens. The process is a time-consuming administrative burden prone to human error. The traditional approach is a system for documenting risk, not for genuinely preventing it. An ai powered hand arm vibration monitoring device is designed to fix this.

| Feature | Traditional Monitoring Approach | The HAVSafe AI-Powered Solution |

|---|---|---|

| Data Source | Manufacturer’s lab data, generic tables | Real-time, on-body sensor measurements |

| Accuracy | Low; based on estimates and assumptions | High; based on actual, individual exposure |

| Exposure Tracking | Manual logs, worker-recalled “trigger time” | Automated, continuous, and precise |

| Alerts | None; data reviewed retrospectively | Real-time haptic, visual, and supervisor alerts |

| Compliance | Burdensome, manual, and prone to error | Automated, auditable, and data-driven |

| Holistic Safety | Ignores worker fatigue and related hazards | Integrates fatigue, stress, and fall detection |

2. The HAVSafe Solution by Softlabs Group

Softlabs Group has developed HAVSafe, a comprehensive ai powered hand arm vibration monitoring device that creates a closed-loop safety ecosystem. Our system protects individual workers, empowers supervisors with actionable, real-time data, and provides leadership with auditable proof of a robust safety program.

Vision & Objectives of the HAVSafe System

Our vision was to transform industrial safety from a reactive, compliance-driven process into a proactive, data-driven system that prevents vibration-induced injuries before they occur. The HAVSafe ai powered hand arm vibration monitoring device makes HAVS a preventable “never event.”

- Accurately Measure and Quantify Exposure: Continuously track each worker’s individual, real-time exposure to hand-arm vibration, adhering to the measurement standards of ISO 5349.

- Provide Real-Time, Actionable Alerts: Instantly notify workers and supervisors when exposure approaches or exceeds legally defined hand arm vibration exposure limits, such as the Exposure Action Value (EAV) and the Exposure Limit Value (ELV).

- Monitor for Holistic Worker Well-being: Move beyond single-hazard tracking to monitor physiological signs of fatigue and stress, identifying when a worker is at an increased risk of injury.

- Automate Compliance and Reporting: Eliminate the manual burden of compliance. The ai powered hand arm vibration monitoring device automatically generates detailed, audit-ready exposure logs and reports.

- Detect and Respond to Acute Incidents: Instantly detect falls or significant impacts, triggering automated SOS alerts to ensure a rapid and effective emergency response.

3. How It Works: The Technology Explained

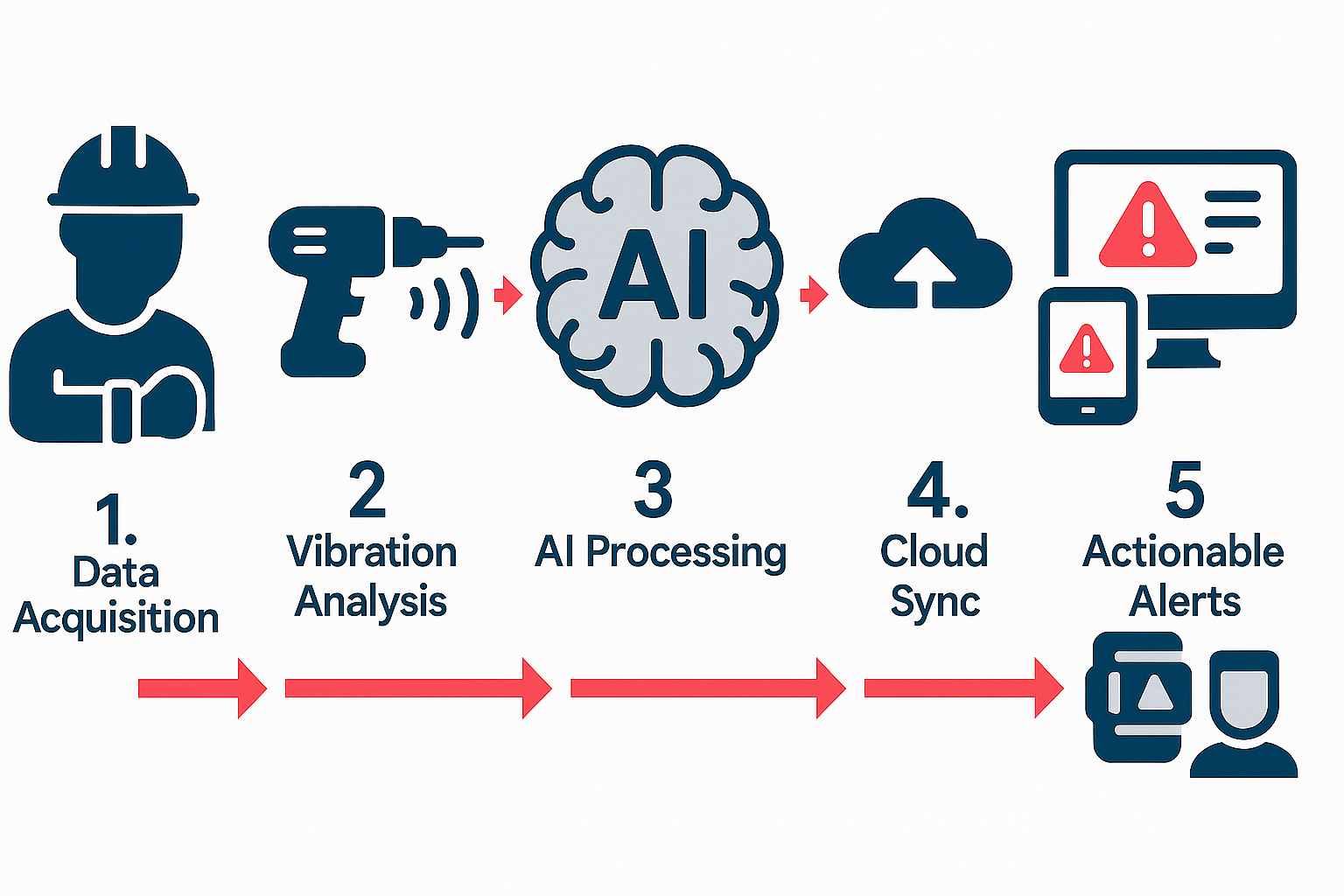

This section explains the process flow of our ai powered hand arm vibration monitoring device, from data collection on a worker’s wrist to actionable safety alerts for a supervisor.

Data Acquisition: The Smart Wearable Sensor Hub

First, the process begins with a worker wearing a smart, ruggedized wrist-worn device. This wearable acts as the central data collection hub. It contains a suite of integrated sensors, the most critical being a MEMS (Micro-Electro-Mechanical System) tri-axial accelerometer, such as the QMI8658C.

This tiny sensor continuously measures acceleration along three perpendicular axes (x, y, and z). It captures the full, multi-dimensional nature of the vibration energy transmitted from a tool to the worker’s hand. This is a requirement for compliance with the ISO 5349 standard.

Simultaneously, an integrated Photoplethysmography (PPG) sensor uses light-based technology to measure blood volume changes at the wrist. From this signal, the system derives vital physiological data, including heart rate, Heart Rate Variability (HRV), and blood oxygen saturation (SpO2). These metrics can help identify potential signs of stress, illness or fatigue.

The AI Processing Pipeline: From Raw Data to Actionable Intelligence

Next, raw data from the sensors streams into the device’s onboard processor. The system then executes a multi-stage pipeline to transform this data into meaningful safety intelligence. This hybrid processing architecture, combining on-device analysis with cloud-based power, is essential.

Immediate safety alerts, like fall detection, require millisecond-level response times only possible with on-device, or “edge,” computing. In contrast, long-term trend analysis and large-scale reporting require the power of the cloud. This synergy ensures both instant worker protection and deep strategic insight.

- Step 1: Vibration Analysis: The raw accelerometer data is processed in real-time on the device. The system applies a frequency weighting, as defined by ISO 5349-1, which emphasizes the most damaging vibration frequencies (typically in the 8-16 Hz range).

- Step 2: Exposure Calculation: The system correlates vibration magnitude with time, measuring the “trigger time” precisely. It continuously calculates the worker’s cumulative daily exposure, converting it into the standardized A(8) value and an intuitive “points” system.

- Step 3: Physiological Anomaly Detection: Concurrently, an AI model analyzes the PPG data stream. The model establishes a personalized baseline for each worker and looks for deviations that indicate the onset of fatigue or high stress.

- Step 4: Fall and Impact Detection: A separate machine learning model analyzes accelerometer data for patterns characteristic of a fall or impact. The model is trained to distinguish a genuine fall from normal work movements.

- Step 5: Data Transmission: Once processed, key insights—vibration points, fatigue alerts, fall events—are securely transmitted to the cloud for storage and deeper analysis. This ai powered hand arm vibration monitoring device ensures efficient data handling.

Output & Interaction: Delivering the Right Information to the Right Person

Finally, the system presents this processed intelligence in targeted ways to ensure immediate and appropriate action. The ai powered hand arm vibration monitoring device creates a seamless communication loop.

- For the Worker: The wearable device provides direct feedback. It may vibrate and display a warning when the worker approaches the EAV, prompting a break. If the ELV is reached, it issues a “STOP” alert.

- For the Supervisor: A real-time dashboard provides an at-a-glance view of the team’s exposure levels. When a worker receives an alert, the supervisor gets an instant notification, allowing for proactive intervention.

- For the Safety Manager: A cloud-based analytics platform provides a high-level, strategic view. Managers can analyze historical data, identify high-risk tools, generate compliance reports, and track safety trends over time.

4. Key Enabling Technologies: The Core of the HAVSafe Solution

Several key technologies converge to make our ai powered hand arm vibration monitoring device possible. Each component plays a critical role in the system’s ability to accurately monitor workers and prevent injury.

- MEMS Accelerometers: Micro-Electro-Mechanical Systems (MEMS) Accelerometers (miniature sensors that measure acceleration) are the heart of vibration detection. A tri-axial MEMS sensor captures vibration in three dimensions, providing the raw data for a comprehensive analysis compliant with ISO 5349.

- Photoplethysmography (PPG) Sensors: PPG Sensors (optical sensors that detect volumetric changes in blood circulation) monitor vital signs. They accurately determine heart rate, HRV, and SpO2, which are key inputs for AI-driven fatigue detection models.

- AI/Machine Learning Models: Artificial Intelligence (AI) and Machine Learning (ML) Models (algorithms that learn patterns from data) serve as the system’s “brains.” This includes models for vibration analysis, fatigue detection, and fall identification.

- Cloud Analytics Platforms: Cloud Analytics Platforms (scalable, server-based infrastructure) provide the backend power. They aggregate data, host dashboards, perform large-scale analysis, and securely store historical data for compliance.

See how our expertise in these core technologies can bring your custom AI solution to life.

Explore Our AI Development Services5. Potential Impact & Benefits for Construction and Industrial Sectors

The implementation of an ai powered hand arm vibration monitoring device delivers transformative benefits that extend from the individual worker to the entire organization. This technology creates a safer and more efficient work environment.

- Drastically Reduced Risk of HAVS: By ensuring no worker exceeds the daily hand arm vibration exposure limits, the system directly prevents the root cause of this debilitating disease, protecting employees’ long-term health.

- Automated and Assured Regulatory Compliance: An ai powered hand arm vibration monitoring device changes compliance from a manual task into an automated process. It provides irrefutable data logs, simplifying audits and minimizing legal and financial risks.

- Enhanced Operational Continuity and Productivity: Preventing injuries leads to a more stable workforce. Research shows that wearable technologies can improve ergonomic conditions by about 38%. Data insights can also help optimize work schedules and tool rotation.

- Creation of a Proactive Safety Culture: The system shifts safety management from reaction to prevention. Real-time alerts empower supervisors to intervene before an injury occurs, fostering a culture where safety is an active, continuous process.

- Data-Driven Decision Making: Management gains objective, quantifiable data on workplace risks. This data can justify investments in lower-vibration tools, prove the effectiveness of new safety protocols, and identify high-risk tasks.

- Improved Incident Response: The integrated fall detection and automated SOS alert system dramatically reduces emergency response times. When a fall occurs, help is dispatched immediately to the worker’s precise location.

Read about the tangible results we’ve delivered for clients across various industries.

View Our Case Studies6. Important Considerations for Implementation

Successfully deploying an ai powered hand arm vibration monitoring device requires careful planning. The data that provides unprecedented safety can also create significant legal and ethical liabilities if mishandled. Therefore, implementation is as much a policy challenge as a technical one.

- Data Privacy and Employee Trust: Collecting health and location data is highly sensitive. Implementation must begin with transparent communication with employees. Policies must align with regulations like the GDPR, clearly stating what data is collected, why it is collected, who has access, and how it is secured. Gaining employee buy-in is essential.

- System Integration and Workflow: The ai powered hand arm vibration monitoring device must integrate smoothly with existing safety protocols. This includes defining clear procedures for responding to alerts, such as the actions a supervisor must take for an EAV notification.

- User Training and Onboarding: Both workers and supervisors need comprehensive training. Workers must understand how to use the device and what alerts mean. Supervisors need training on using the dashboard and responding effectively to notifications.

- Infrastructure and Connectivity: The worksite must have reliable connectivity, whether through Wi-Fi, cellular, or an IoT network. This ensures that data from the ai powered hand arm vibration monitoring device can be transmitted to the cloud platform in a timely manner.

- Scalability and Maintenance: The chosen solution must be durable enough for harsh industrial environments and scalable to the entire workforce. This includes considering battery life, device maintenance, and the need for ongoing software updates.

- Accuracy and Potential for Bias: The accuracy of wearable sensors can vary, and AI models can reflect biases from their training data. It is critical to select high-quality hardware and continuously validate the performance of the AI models across a diverse workforce.

7. Deploying a Proven Solution: Tailoring HAVSafe for Your Needs

The HAVSafe ai powered hand arm vibration monitoring device described here is a powerful, field-proven platform developed by Softlabs Group. While it offers a comprehensive solution out-of-the-box, we understand every worksite has its own specific tools, tasks, and environmental challenges.

True effectiveness comes from tailoring this ready-to-use technology to your specific operational needs. Softlabs Group specializes in this customization. Our expertise lies in deeply understanding your unique challenges to adapt the HAVSafe platform, ensuring it integrates seamlessly into your workflow.

We partner with you to deploy a solution that is truly your own. We will address your highest-risk areas and deliver measurable improvements in worker safety and compliance, creating a perfect fit for your hand arm vibration ai solution india needs.

Ready to discuss how a tailored AI solution can solve your specific safety challenges?

Discuss Your Custom AI Project